Building on last week’s exploration of different materials and styles of metal roofs, today’s #MagnificentMetalMonday delves into the best coating options. In our previous blog, we highlighted popular metal roof materials like aluminum, copper, zinc, and steel — known for their durability, rust resistance, reflectivity, and energy efficiency. Now, let’s explore how quality finishes and coatings enhance these qualities, offering a wide range of benefits and styles. The right coating not only achieves a desired look but can also address specific issues, and add years to a roof’s life.

Picking the right substrate and coating combination will determine the quality of your roofing project, the long-term beauty of your metal roof, and ultimately the return on your investment. The best roof coating is the coating that protects from all forms of damage.

Metal Roofing Substrates

Underneath the paint/coating, the substrate of the actual metal is the heart of a metal roof panel. There are two common steel substrates available today, Galvanized and Galvalume®. Galvanized substrates feature a zinc coating applied to the raw steel while Galvalume substrates feature an alloy of zinc plus aluminum.

Galvanized: There are different levels of quality; for example, two common galvanized substrates are known as G100 and G60. The numerical designation refers to the amount of zinc contained on both sides of the panel surface. The higher the amount of zinc, the more resistant the panel will be against corrosion. With 66% more zinc than G60 substrates, G100 substrates will last far longer than their G60 counterparts. The performance difference is significant enough to state that G60 substrates are not considered appropriate for residential roofing.

Galvalume®: The addition of the aluminum alloy enables Galvalume substrates to outperform galvanized for the long-term. Galvalume delivers better results, excellent corrosion resistance, and long-term aesthetics. Galvalume substrates also carry a warranty from Steel Mills against rupture or perforation due to corrosion.

Metal Roofing Coatings

Polyester systems are the least expensive option but are also the lowest-performing. With the greatest potential for chalk and fade, polyester systems have the shortest lifespan and are not typically recommended for residential roofing. In today’s market, better-performing coatings include Silicone and Polyvinylidene Fluoride or PVDF paint systems.

Silicone-Modified Polyester (SMP) – A better-performing option than polyester systems; the SMP paint systems will still experience fade and chalk, but not to the same degree as polyester coatings. Silicone coatings are also commonly used for commercial roofs since they promote durability and prolong the roof’s lifespan. They enable metal roofs to expand and contract according to temperature changes. Additionally, the coating typically comes with a 10 to 20-year warranty.

PVDF (Kynar 500®) – Regarding service life, color retention, and chalk resistance, PVDF (Polyvinylidene Fluoride) systems rank superior and will offer a like-new appearance year after year. PVDF is a fluoropolymer resin that is highly inert and stable, providing excellent resistance from metal weathering over time. PVDF coatings can be applied to metal both before and after forming.

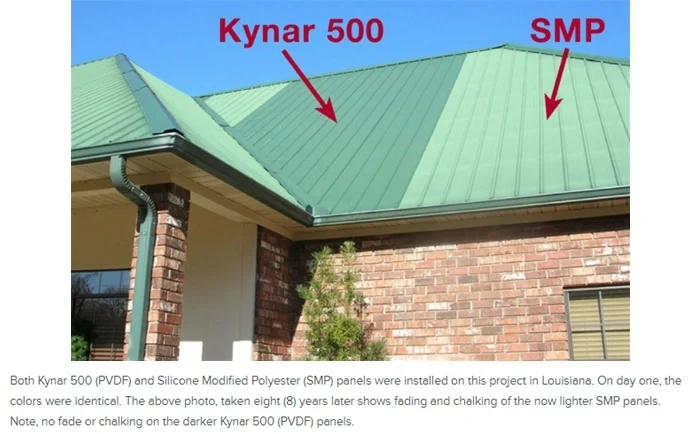

The image below shows a home that had the same color SMP and Kynar 500 coated panels installed. Eight years after installation, the image below was taken. Notice the stark contrast in performance between the two systems. The Kynar 500 roof still looks new while the SMP roof has experienced significant fade and chalk.

Factors to Consider When Selecting a Coating

- DURABILITY: Although metal roofs are made of durable materials, including steel and aluminum, adverse weather conditions can still damage them and durable coatings help prevent them from weather damage.

- CORROSION RESISTANCE: Since metal roofs are naturally susceptible to corrosion and rot, select a coating that is corrosion-resistant.

- WATERPROOFING: One of the main advantages of applying a roof coating is water resistance to prevent the metal roof from the adverse effects of ponding water which can increase the rate of rust formation on metal surfaces.

- UV RESISTANCE: Though metal roofs are highly reflective, the coating should be able to withstand harmful and intense UV rays.

- FLEXIBILITY: Metal roofs can experience thermal expansion, causing nails to pop up and the metal panels to move, creating gaps for water to seep through. The coating should have flexibility to keep the metal sheets intact and fastened to the roof deck. Elastomeric coatings are the best fit for this purpose.

- ADHESION: Look for a coating that’s been tested to meet adhesive standards. For best results, allow the coating to dry for 24 hours, or longer depending on the type of coating, to ensure that it’s fully adhered to the roof.

- LOW MAINTENANCE: A coating that requires minimal maintenance can help reduce the overall cost of maintaining the roof and the amount of time and effort required to keep the roof in good condition.

In summary, when selecting the right type of coating, it is critical to first consider the type of metal roof along with the climate and weather conditions for the structure, whether it’s residential or commercial. One of the most important factors to consider is the type of metal roof you have since different types of metal roofs may require different types of coatings. Choosing a coating compatible with your particular type of metal is important. Secondly, if your roof is exposed to harsh weather conditions, such as heavy rain, snow, or high winds, you’ll want to choose a coating that provides good water resistance, durability, and UV resistance.

To delve deeper into the world of metal roof coatings and gain insights from an industry expert, check out our recent METALCON Online Webinar. Learn from Architectural Manager, Gary Edgar of PPG, in his presentation “Architectural Uses for Liquid & Powder,” as he deciphers the disparities between liquid and powder coatings and the nuances of various powder coatings, including the revolutionary powder fluoropolymer coating technologies. Gain insights into the technologies for architectural markets, explore the diverse range of coating technologies currently available, delve into the manufacturing process of these products, and discover specific application methods to elevate your expertise.