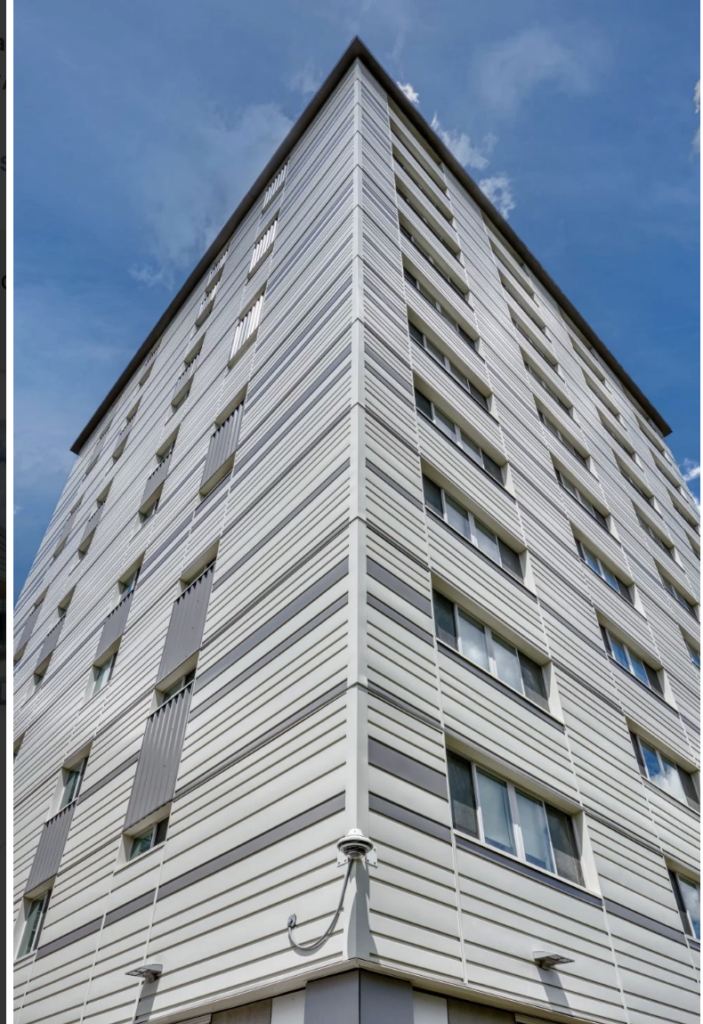

In today’s discussions about optimizing a building’s overall performance, architects, designers, and contractors are increasingly focusing on superior moisture management and energy efficiency. Rainscreens have emerged as a pivotal solution in this context. They not only significantly enhance a building’s energy efficiency but also provide essential protection for the primary building envelope, making them an indispensable component in modern construction practices.

What is a Rainscreen Wall?

According to RAiNA (The Rainscreen Association in North America), “A rainscreen is defined as an assembly applied to an exterior wall which consists of, at minimum, an outer layer, an inner layer, and a cavity between them sufficient for the passive removal of liquid water and water vapor.” Rainscreens are effective at managing moisture and provide exceptional opportunities for energy-efficient performance via continuous insulation and reducing thermal bridging. Assemblies that fall into this definition range from masonry, to clip and rail, and pressure-equalized systems.

Rainscreens are a critical step in the building assembly. After surveying companies, asking them what the most problematic terminology they struggled with while facing customers/stakeholders and at what frequency, RAiNA’s Definitions Committee took great care to formulate the rainscreen definition. After identifying 189 terms problematic, the Committee came to the conclusion that a comprehensive definition of rainscreen was necessary to bridge the communication gap within the construction industry.

How Does a Rainscreen Wall Work?

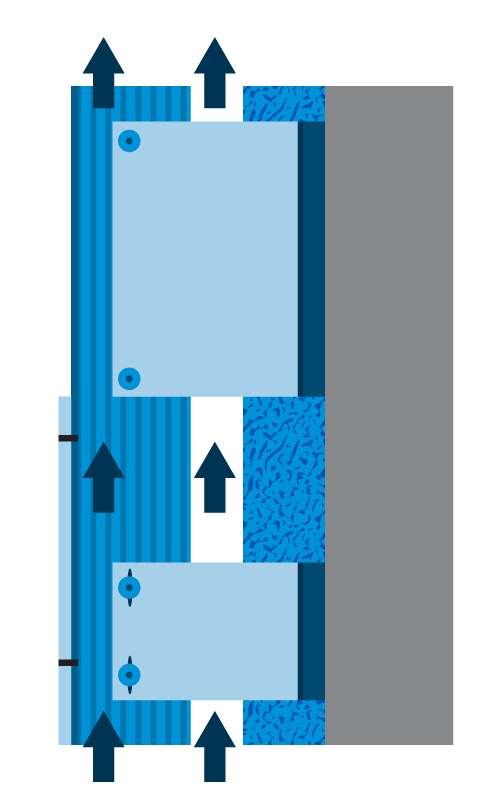

A rainscreen wall is a construction system designed to protect buildings from water intrusion while providing a means for moisture to escape and air to circulate, thereby enhancing the durability and energy efficiency of the structure. It is an exterior cladding infrastructure that sits away from a building’s exterior wall’s water-resistant barrier, creating an air cavity directly behind the cladding which is vented at both the top and bottom of the wall so it helps to protect the building’s important envelope.

The key components and mechanism of rainscreens include:

- Exterior Cladding – the outermost layer acting as a shield from direct rain impact

- Air Gap – exists between the exterior cladding and the inner layers of the wall allowing for ventilation and helping to dry out any moisture that penetrates the cladding

- Water-Resistive Barrier (WRB) – typically a water-resistant barrier such as a house wrap that lies behind the air gap providing an additional one of defense against moisture

- Drainage Plane – found within the air gap, allowing for water to flow down and out through weep holes or flashing at the base of the wall

- Thermal Insulation – typically placed in the cavity or on the interior side of the WRB to help maintain the energy efficiency of the building

- Vapor Barrier – used in climates where vapor control is crucial

These components enable the rainscreen to deflect, drain, dry and equalize the pressure, allowing an important layer of protection of the building envelope.

Benefits of Integrating Rainscreen Walls

Enhanced Design Flexibility and Durability

- Provides great design flexibility, works with a limitless variety of options for simplified detailing and transitioning between cladding materials.

- By preventing moisture intrusion and facilitating drying, rainscreen walls extend the lifespan of the building materials and structure.

Improved Energy Efficiency and Sustainability

- Water vapor behind cladding and insulation can escape by means of evaporation.

- Helps reduce hot and cold air and thermal movement through the wall, reducing energy costs.

- Enables more insulation, within the stud cavity and more effectively on the exterior of the wall.

- Reduction in the buildings dead load by use of lightweight cladding options versus traditional building materials (i.e. brick veneer, etc.).

Reduced Maintenance

- By keeping the structural elements dry and preventing moisture-related damage, rainscreen walls reduce the need for maintenance and repairs.

- Air space between exterior cladding and drainage plane helps drainage and facilitates ventilation and drying.

Register for METALCON’s Rainscreen Wall Courses to Learn More!

In four short months, industry professionals will gather at METALCON 2024 in Atlanta, GA, to learn, network and see the latest innovations in the metal construction and design industry. “Providing education on building performance at METALCON is essential,” says Judy Geller, Vice President, METALCON. “It will help building and design professionals address performance challenges, mitigate risks and enhance resilience leading to cost savings over the lifespan of the building. Standards and codes specific to the building site provide a helpful path to improving building performance. Understanding the performance capabilities of products used in construction will certainly help building and design professionals erect higher-performing buildings.”

Learn more about overall building performance and the role rainscreens play by registering for METALCON today. Check out these FREE education courses being offered:

- What Makes Rainscreen Walls Work – October 30 at 10:30 am in the Technical Know-How Learning Center presented by RAiNA

- How Can a Rainscreen be a High Performance Envelope Option? – October 30 at 1:15 pm in the Building Performance Learning Center presented by RAiNA

- Insulated Composite Backup Panels – November 1 at 10:30 am in the Building Performance Learning Center presented by Kevin Franz with Nucor

METALCON Online Free Webinar takes Closer Look at Rainscreens

Last year, METLACON Online and RAiNA teamed up to present “What Makes Rainscreen Walls Work.” RAiNA Chair, Todd Kimmel, CPHD, CDT, provides a comprehensive understanding of how rainscreen walls work and their key benefits. You can watch from METALCON’s ON DEMAND library at your convenience and earn 1.0 AIA LU HSW credit.