#MagnificentMetalMonday looks into the advantages and benefits of prefab modular construction and why it will play a role in shaping the future of metal construction. According to the US Modular Construction Market report by Grand View Research, “Steel led the U.S. modular construction industry with the highest revenue share of 41.4% in 2022 and is expected to grow significantly over the coming years.”

What is Modular Construction?

According to the Modular Building Institute, “Modular construction is a process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities – but in about half the time. Buildings are produced in “modules” that when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.” There are two types of modular construction: permanent and relocatable.

According to the Grand View Research report, “In prefabricated building activities in the U.S., structural steel is used as a building material, which is available in different grades and can be welded into different shapes. It is used in the development of H-type beams, columns, angles, I-beams, and T-shaped structures. The material exhibits excellent mechanical and chemical properties such as high strength, durability, ductility, seismic resistance, and fast installation, along with offering ease of fabrication.”

Benefits of Prefab Modular Construction

Plain and simple — modular construction is greener, faster and smarter. The factory-controlled process generates less waste, creates fewer site disturbances and allows for tighter construction. Construction of modular buildings occurs simultaneously with site work, allowing projects to be completed in half the time of traditional construction. Modular buildings are built with the same materials and to the same building codes and architectural specifications as traditional construction. Once assembled, they are virtually indistinguishable from their site-built counterparts.

Why Prefab Modular Construction is Greener

According to BuildingGreen, “Proponents of modular construction believe it can deliver greater environmental and social sustainability benefits than conventional construction can.” Based on research conducted by McGraw-Hill Construction, the following common claims for the sustainability benefits of modular construction include:

- reduced material waste

- reduced disruption to the building site and surrounding community

- safer working conditions

- reduced operational energy

Why Prefab Modular Construction is Faster

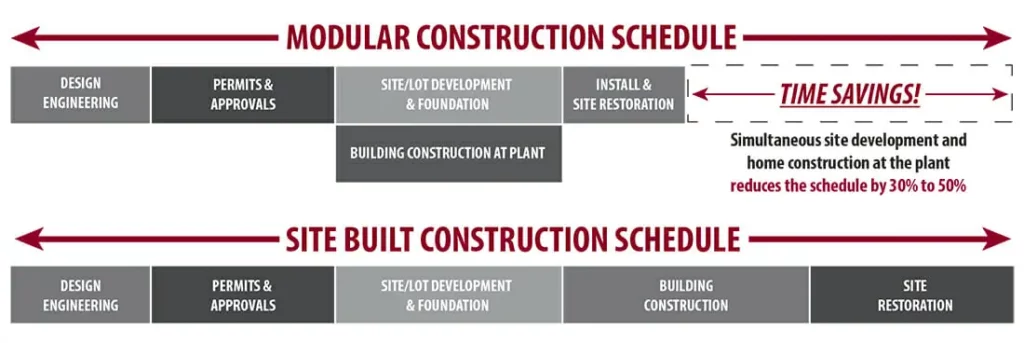

In the same research conducted by McGraw-Hill Construction, modular construction has been shown, in a majority of cases, to result in a higher-quality building delivered in a shorter time frame with more predictable costs. Modular Building Institute cites why modular construction is faster: reduces the construction schedule because construction of modular buildings can occur simultaneously with the site and foundation work, elimination of weather delays because 60 – 90% of the construction is completed inside a factory, and it can be built to code with quality materials.

Take for example the Peppers Kings Square Hotel (PKS) in Perth, Australia. This 120-all suite hotel opened in 2017, having been completed in just 11 months, with the main building components being the main structural and façade elements and the bathrooms, installed in only 11 weeks. According to PTI Architecture, the designers for the PKS Hotel project, explains the savings in cost and time as being reasons for turning to prefabricated modular construction. They highlight the following two reasons:

- The quality of the interior fitout is much higher than for a traditional project being so much of the works are made under controlled factory conditions and not on a busy building site.

- Using prefabrication enables us to use far less carbon intensive materials, have far less waste and also use far less energy and water usage throughout the construction process.

To watch a video of the construction process, please see the following link.

Why Prefab Modular Construction is Smarter

In addition to being greener and faster, prefab modular construction is also a safer construction model, has limitless design opportunities and is ideal for the use of BIM technology, leading to better and smarter engineered buildings.

The PKS Hotel is also a case study in why prefab modular construction is a smarter model. METALCON’s recent keynote speaker, Christian “Boo” Boucousis, CEO of global organizational performance at Afterburner, comments on his team’s involvement with the project. “I can unequivocally say that this hotel will be a worldwide game-changer thanks to the incredible project team involved. The PKS project broke Australian construction records and challenged traditional industry cost structures like never before!” By utilizing prefabricated modular technology for the whole building, the unique features of this project include:

- The quickest and tallest 17 level high-rise construction in Australian history – 11 months

- Costs — 20% lower than the industry standard

- Waste — 90% less than the industry standard

- Fastest WiFi out of hotels in the country

- “Customer Experience” model delivered over “Customer Service” mode

According to Hickory Building Systems, the project’s contractor, they reduced the overall construction program by prefabricating the majority of the project structure, façade and bathrooms off-site. Their patented façade system enabled the building exterior to be completed prior to delivery, with the striking glass façade accentuated by perforated sun-shade screens spanning floors 2 – 17.

Overall, modular construction has gained popularity and a lot of attention in recent years due to its potential to accelerate construction timelines, reduce costs, use less carbon intensive materials, and provide flexibility in design. Prefab steel buildings are in demand because of their benefits. They’re strong and durable against the elements, versatile, customizable, and can save you time and money because they’re easy to build.