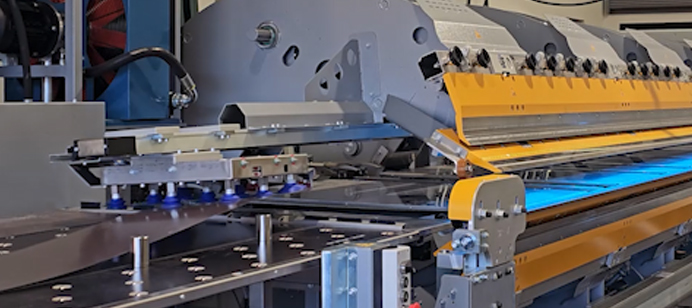

Shaping Tomorrow’s World with Innovation and Efficiency

Over the past months, Thalmann’s product development team has been working hard to develop the next innovation towards further automation with the Multi-Head Side Loader. Built to pair with the Thalmann TD Double Folder, the Multi-Head aims to increase the efficiency of the existing automation packages offered by CIDAN Machinery Group. Below is a breakdown of what makes the product stand out from all other products, including Thalmann’s first-to-the-market original side loader. This new development aimed to further the ability of automation with the TD Double Folder systems while also decreasing cycle times for our customers. The Thalmann product development team did it again and accomplished just that: increased automation and speed.

Here’s why the Multi-Head Side Loader TD is a true game-changer:

Faster Loading for Increased Productivity

- We all know time is money, and the Multi-Head Side Loader feature allows you to maximize efficiency further. When Thalmann designed the side loader, we learned that the shuttle mode of picking-loading-dropping one blank at a time was a strong advancement in automation but had room for improvement. We designed a wider system with 48″ (1250mm) of coverage and, most importantly, the ability to pick up to 4x blanks at a time. This multi-pick function pulls multiple blanks into the system and drops them into different gripper zones within the machine. From here, the automated forming starts in the TD Double folder. With this capability, we calculate an improvement of loading times +40% faster than Thalmann’s original side loader design, leading to significantly increased throughput. Imagine the impact this efficiency boost will have on your production schedule.

Increased Capacity and Durability

- With the ability to handle a wider 48″ (1250mm) coverage, we also increased the system’s strength. With 16 suction cups delivering a 30% boost in suction force for improved efficiency, the Multi-Head Side Loader provides the holding power needed for our primary market base. The system also automatically adapts to the material selected by the TD’s control, handling thinner metal up to the machine’s capacity.

Automation and Blank Feeding

- The auto-adjusting side loader tables adjust the table height to keep the side loader infeed height and the stack of blanks even. The Multi-head is equipped with an ultrasonic sensor that ensures precise height measurement of your stock. With the table capacity of 268 lbs. per linear foot, there is plenty of capacity to keep the machine running while the next set of blanks is being prepared. As in the original version, the loading tables are pneumatically lowered until the caster wheels can move the table to your coil processing area. With just two sets of tables, you can keep the operation running with minimal downtime.

- It’s paired with user-friendly software that allows you to control loading preferences, from loading a single blank to multiple blanks simultaneously, making it easy to guide materials into optimal positioning. Flexibility meets precision with every load, ensuring seamless operation every time.

Easy Programming and Versatile Loading for Various Sizes

- Like all the automation within the Thalmann umbrella, the software engineers integrated the Multi-Head with the DS3000 control with ease of use and centralized input in mind. Whether you’re looking to automate the handling of multiple blanks as narrow as 3.54 inches or working with wide blanks for applications such as wall panels, the control handles the optimization of programming effortlessly. When operating in section mode, this machine becomes your go-to solution for handling just a few SKUs to thousands of jobs.

Phased Automation Concept

- Its CIDAN Machinery Group’s strategy to work not only towards automation but also to create possibilities for incremental automation for our customers. The Multi-Head Side Loader was designed to be retrofittable on many existing TD machines and an aftermarket add-on with new TD purchases. We do this to partner with our customers by making automation a build-up process over time. These phased automation options make the purchase of the base machine less capital-intensive from the start. Of course, there are some restrictions with older machines from controls, existing automation drives in the machine etc.

Being Our Customer’s Partner

At CIDAN Machinery Group, we are dedicated to understanding our customers’ future needs and helping push the limits of what’s possible in sheet metal processing. As your One-Stop Partner, we offer not just machines but comprehensive solutions. With the demand for automation increasing week over week, we strive to be the leader within our niche of the sheet metal machinery market. The Multi-Head Side Loader TD is a testament to our commitment to this strategy. Together, we’re shaping tomorrow’s world.

For more information, contact us here:

https://cidanmachinery.com/us/contact-us

Vote for Top Products at METALCON here:

https://cidanmachinery.com/VOTE_multi_head_side_loader

Discover our latest innovations at METALCON by visiting:

https://cidanmachinery.com/us/metalcon2024

Ready to take your operations to the next level?

The Multi Head Side Loader TD is your answer – a smart solution for today’s fast-paced sheet metal industry. Experience the future of sheet metal processing today.