In an era of increasing wildfire risks and stricter building codes, non-combustible construction is more important than ever. From commercial high-rises to residential communities in fire-prone areas, builders and architects are turning to fire-resistant materials and innovative fireproofing techniques to enhance safety and resilience. But what exactly qualifies as non-combustible construction, and how do metal buildings fit into the equation? This blog explores the classifications, emerging fireproofing technologies, real-world case studies, and the role of the AEC community in rebuilding after disaster strikes.

What is a Non-Combustible Building?

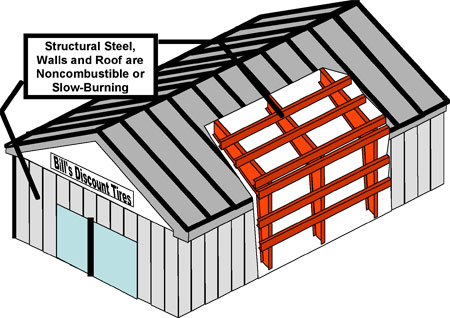

A “non-combustible building” is a structure constructed entirely from materials that do not ignite or burn easily, like steel, concrete, and masonry, meaning the building is highly resistant to fire and does not contribute fuel to a blaze when exposed to flames. Non-combustible construction includes non-combustible materials like steel, concrete, brick, stone, and certain types of insulation. Combustible materials are at risk of catching fire and spreading the fire to other parts of the building, whereas noncombustible materials are materials that do not burn or ignite when exposed to heat or fire. A building’s structural elements and fire-resistance ratings determine its construction type and classification, including non-combustible construction.

Non-Combustible Construction Types and Classifications

Three governing bodies provide building construction types and classifications:

1. The National Fire Protection Association (NFPA) defines construction types and classifications in the NFPA 220, Standard on Types of Building Construction

2. The International Building Code (IBC) defines construction types and classifications in Chapter 6, Types of Construction.

3. The Insurance Services Office (ISO) defines construction types and classifications on its website’s Construction Briefs page.

In order for a building to be considered fire resistive, non-combustible construction, it must receive a Type I and II NFPA classification.

How Some Homes Survived the LA Fires

As watched the tragedy unfold in Los Angeles and Southern California, with over 12,000 homes lost and over 75 people’s lives’ lost, how have some homes survived while so many have been reduced to ash and rubble? Several fire-resistant design strategies left some structures standing in devastated areas. These resilient structures could provide the basis of revamped design strategies to rebuild neighborhoods laid waste by the disaster.

One home in particular that survived in the Palisades area was designed using the following fire-resilient design strategies:

- Yard was largely free of vegetation and fenced off by cast-in-place concrete garden walls.

- Simple design with “Monopoly framing” for roof and overlays.

- Metal/steel roof with special underlayment designed for fire; no attic vents to allow sparks to get inside.

- Walls of the house have a one-hour fire rating.

- Deck is Class A wood, which is as resistant to ignition as concrete or steel.

- Tempered glass windows to protect the interior.

- Front of the house was built with heat-treated wood, shielded from airborne embers by extruding walls and roof line.

Check out more on this by architect BYoungDesign.

Another home by famous celebrity, Tom Hanks, also went viral for having survived the fire, perhaps because of having implemented the following strategies: defensible space around home, metal roof, rock on roof, no soffit fence or overhangs making it more airtight, and a concrete barrier on one side.

Watch the Build Show with Matt Risinger to learn more.

Are Metal Buildings Considered Non-Combustible?

Most metal buildings fall under the classification of non-combustible construction. This means the primary structural elements are made of non-combustible materials like steel, providing fire resistance. Fire protection ensures the safety of building occupants and first responders and the structural integrity of steel buildings.

The increasing complexity of modern building designs, paired with the demand for protection and aesthetic appeal, makes it essential for design teams and contractors to choose specialized fire protection technologies and implement complete testing of fire-stopping systems to help avoid catastrophic events.

Fire Retardant Construction and Modern Building Codes

Homes built to meet or exceed modern building codes are significantly more fire-resistant than those constructed decades ago. The 2023 Maui wildfire provided a stark contrast between buildings that followed updated codes and those that didn’t. According to Building Construction + Design and the Insurance Institute for Business and Home Safety (IBHS Early Insights Lahaina Fire—2023), certain fire-resistant features helped protect structures from destruction, even in tightly packed developments. These included:

- High wind-rated attic vents, preventing embers from infiltrating attic spaces

- Class A roof covers, with metal and asphalt shingles providing superior fire resistance

- Non-combustible exterior wall materials, reducing fire spread

As wildfires become more frequent and intense, implementing modern fire-retardant construction methods isn’t just recommended — it’s essential for resilience and long-term safety.

However, opinions often differ on how to strike the right balance between ensuring public safety and streamlining housing development. While some argue for stricter codes and fire-resistant materials to protect communities, others emphasize the need for flexibility in codes to accelerate rebuilding and address housing shortages. As the AEC community comes together to rebuild, finding that balance will be key to creating resilient, sustainable communities.

TWO GREAT RESOURCES TO LEARN MORE: Read NFPA’s Preparing Homes for Wildfire and Watch this Training Video on Understanding the Wildfire Threat to Homes.

Rebuilding in the Wake of Destruction: Join the AEC Community in Making a Difference

PSMJ Resources, producers of METALCON and leaders in the AEC community, invite you to join the re-launch of the PSMJ Disaster Rebuilding Fund, a 501(c)(3) organization founded after Hurricane Katrina to support long-term rebuilding efforts. Unlike immediate relief efforts, the fund focuses on reconstruction projects that often fall out of the mainstream spotlight. Past efforts include building a 10,000-square-foot Community Hall in Bay St. Louis, Mississippi, symbolizing hope and renewal. Currently, the fund is helping Hot Springs, North Carolina, rebuild its public library after Hurricane Helene while monitoring the devastation in Southern California to identify future rebuilding opportunities.

Every contribution — whether skills, time, or resources — makes a difference. Let’s unite to create a brighter future, be the architects of change, and the engineers of hope. Donate today.