Throughout this month, we’ve delved into the diverse world of metal roofing, comparing its various types and styles, exploring its contrasts with asphalt, and looking at the types of metal roof coatings. As we round out the month, today’s #MagnificentMetalMonday focuses on the crucial role of underlayment in metal roof installations. Understanding the significance of choosing the right underlayment is paramount, as it holds equal weight to the selection of the roofing material itself, be it for a residential or commercial project.

What is Underlayment?

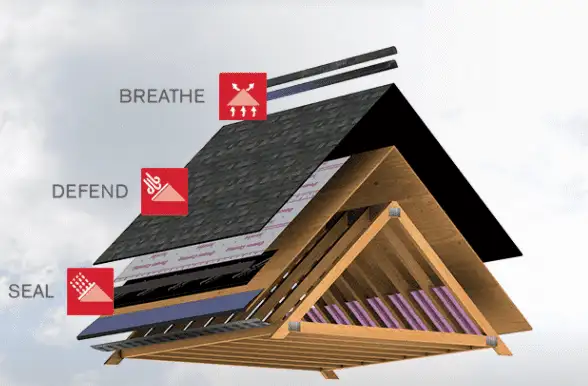

Underlayment is the layer beneath a roofing system that serves as an extra weather resistance barrier — a secondary level of waterproofing protection directly on top of the wood roof deck. As a crucial barrier that contributes to the performance and longevity of the entire roof system, it is important to choose the right underlayment for your roof and your particular climate. This layer of protection isn’t optional — it’s essential to a proper metal roofing system. Three common types of underlayment for metal roofs include felt, self-adhering membrane, and synthetic sheet.

What’s the Best Underlayment Choice for your Metal Roof?

It’s important to create the best support system to provide the best protection for your roof and home. Here are some things to keep in mind when considering the three common metal roofing underlayment options:

Felt Underlayment

Felt underlayment is the most common material used for steeper-sloped metal roofs. Known to be cost-effective and reliably water-resistant, but it does not last as long as other underlayment materials and is likely to fail before a metal roof needs replacing. Climate is another consideration as it tends to not endure high-temperature environments very well. Some other notable disadvantages include small roll sizes leading to increased labor and lack of recyclability.

Self-Adhering Membrane

Self-adhering membrane underlayment is a peel-and-stick product that includes either a rubberized asphalt or butyl-based adhesive, mounted on a polyethylene carrier sheet, and designed to be applied directly to roof decking. Known to perform better than felt underlayment in high-temperature environments, the self-adhering membrane presents more of an air barrier. It is more helpful for ice dam protection in sensitive locations like eaves, valleys, and dormers. Other factors to consider with this underlayment include installation and its performance in low-temperature environments. If not installed correctly, it can result in your membrane peeling back over time, leaving a roof more vulnerable to infiltration.

Synthetic Sheet

The “new kid on the block.” Synthetic underlayment is a newer technology that’s become more prevalent in recent years. It’s manufactured by weaving or spinning together either polyethylene or polypropylene with a polymer, to form a protective barrier between the roofing material and decking. The advantages include durability, high temperatures tolerant, and the longest lifespan. While more expensive than some comparable underlayment options, synthetic underlayment currently provides the most reliable performance at keeping out moisture and has better product longevity.

Tips on Choosing the Underlayment Right For Your Roof

According to Sheffield Metals, a METALCON exhibitor and leading distributor of coated and bare metal products, as well as engineered standing seam metal roof (SSMR) & wall systems, they suggest asking yourself these questions to help determine which underlayment is right for you:

- How long do I want the roof underlayment to last? How about the actual roof?

- Does my or my customer’s budget allow for an expensive underlayment?

- Will my or my customer’s underlayment be exposed to long periods of sun or heat?

- Do I want to be able to buy my underlayment at a big box/home improvement store?

- How concerned am I about fire resistance or having a Class-A fire rating?

Continuing Education with Roofing Experts

According to the Metal Roofing Alliance, a new CEU continuing education course is now available for architects and other roofing professionals about roofing underlayments called The Importance of Roof Underlayment for Energy Efficiency and Fire Resistance. Offered by Westlake Royal Roofing Solutions™, a leader in efficient and resilient roofing systems and components, the course explores the roof underlayment as an integral part of the total roof system design and educates architects on the performance, benefits, fire resistance and weather resilience of various underlayment types. The course explores the different types of underlayment, highlighting options that will optimize the performance and compatibility with roofing materials. It will also examine the attributes and strengths of the different underlayment categories and educate participants on how quality products can enhance energy efficiency and fire resistance.

Meet with Experts at METALCON

For over 30 years, METALCON has been a leading event for the metal construction industry. With nearly 20 exhibitors specializing in metal roofing materials, including underlayment products, slated to participate in this year’s event, you’ll have the exclusive opportunity to explore these offerings firsthand. Leading companies such as Sheffield Metals, Isaiah Industries, Titanium® and RhinoRoof, and VB Synthetics will be on hand showcasing their latest roofing solutions and products. Join us this year in Atlanta, Georgia, October 30 – November 1, for 3 days of connecting with industry experts and peers from around the world.

For more information:

Synthetic vs. Felt Underlayment for Metal Roofing: Which Is Best? by Sheffield Metals

CHOOSING THE RIGHT UNDERLAYMENT FOR YOUR METAL ROOFING INSTALLATION by Skywalker Roofing

What is the Best Underlayment for a Metal Roof? by McElroy Metals