In construction today, “metal roofing seamers” primarily refer to power-assisted mechanical tools used to create tight, weatherproof seams on standing seam metal roof panels. These tools are integral to modern roofing systems for several reasons: they enhance durability, improve energy efficiency, and offer unmatched design flexibility. Metal roofing seamers have become an essential component for contractors striving to deliver high-quality, long-lasting installations.

Why is seaming equipment one of the most valuable tools in construction today? In this blog, we dive into answering that question by exploring the evolution of metal roofing installation, the types of panel engagements, and the latest advancements in seaming technology — including a spotlight on Malco Tools’ new and award-winning Power-Assisted Seamer and Cutter.

One of Your Most Valuable Tools in Metal Roofing

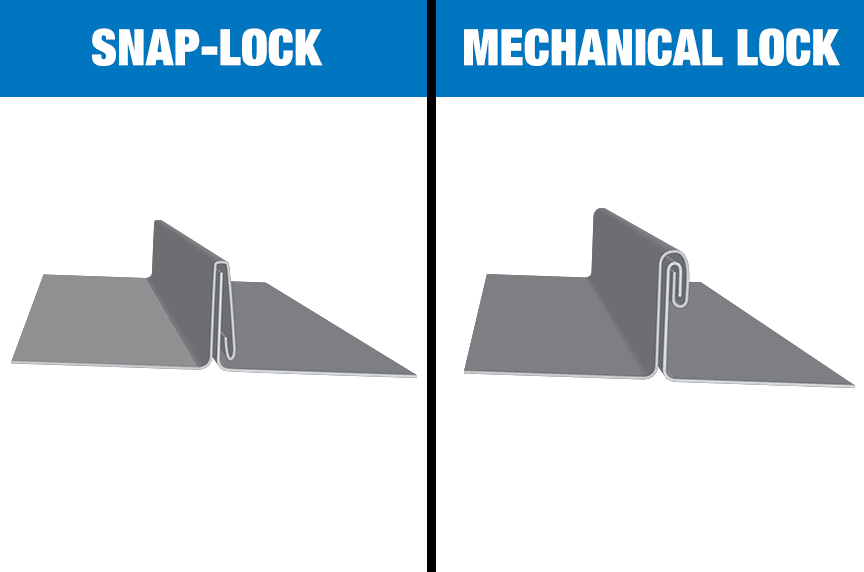

In the early days, metal roofing was installed with hand-forming tools, crimpers, pliers, and folders. As the product line improved throughout the years, the art of joining the individual panels evolved as well. The fine art and skill required to create an attractive and functional seam has been refined and divided into two modern-day categories: mechanically seamed roofing and snap-lock seamed roofing.

The seaming process endures as the real art of the installation of a metal roof. Most modern options are electric-powered machines that can precisely bend and crimp the metal panels together, often with interchangeable tooling to accommodate different panel profiles.

Types of Panel Engagements

The two primary methods of panel engagement include Snap-Lock seamed roofing and Mechanically seamed roofing.

Snap-Lock

Known as a foolproof method for joining metal panels without the use of complicated tools or metal working skills. Most snap-lock panel systems are primarily used at or above a 3:12 pitch. Snap-lock panels are typically thought of as water-shedding systems, requiring underlayment to maintain their weathertight integrity. As expected, the male/female legs on snapped panel systems snap in place due to their design.

During installation, the vertical legs are positioned over each other, and pressure is applied to push the upper panel down onto the lower panel until the legs properly engage. Typically, the snap condition is accomplished with simple pressure by hand, although sometimes a rubber mallet is also used. While it varies based on the panel design, some systems, such as ASTM E 1592, can meet rigorous uplift tests.

Mechanically Seamed

Today’s seamers, both electrically driven and their associated hand tools (to start and finish metal seams) have advanced along with the metals and finishes we use now. Unlike snapped panels, mechanically seamed panels require a motorized seaming machine to complete the installation and panel engagement.

During the seaming process, the mechanized machine folds two or more panel legs together, forming a much stronger connection than their snapped-style counterparts. Mechanically seamed systems perform well on lower slope roof systems (think 2:12 and below), projects with high wind uplift, and stringent weather tightness warranty requirements.

With seaming machines typically running between 30-50′ a minute, they are highly efficient and can save time with the metal roof installation.

Want to Learn More?

For a detailed explanation of the differences between mechanical lock and snap-lock metal roof profiles, check out this resource from New Tech Machinery, a METALCON exhibiting company and a trusted name in the metal roofing industry. The guide includes an insightful video that breaks down the key distinctions and applications of each system — perfect for those looking to deepen their knowledge of metal roofing profiles.

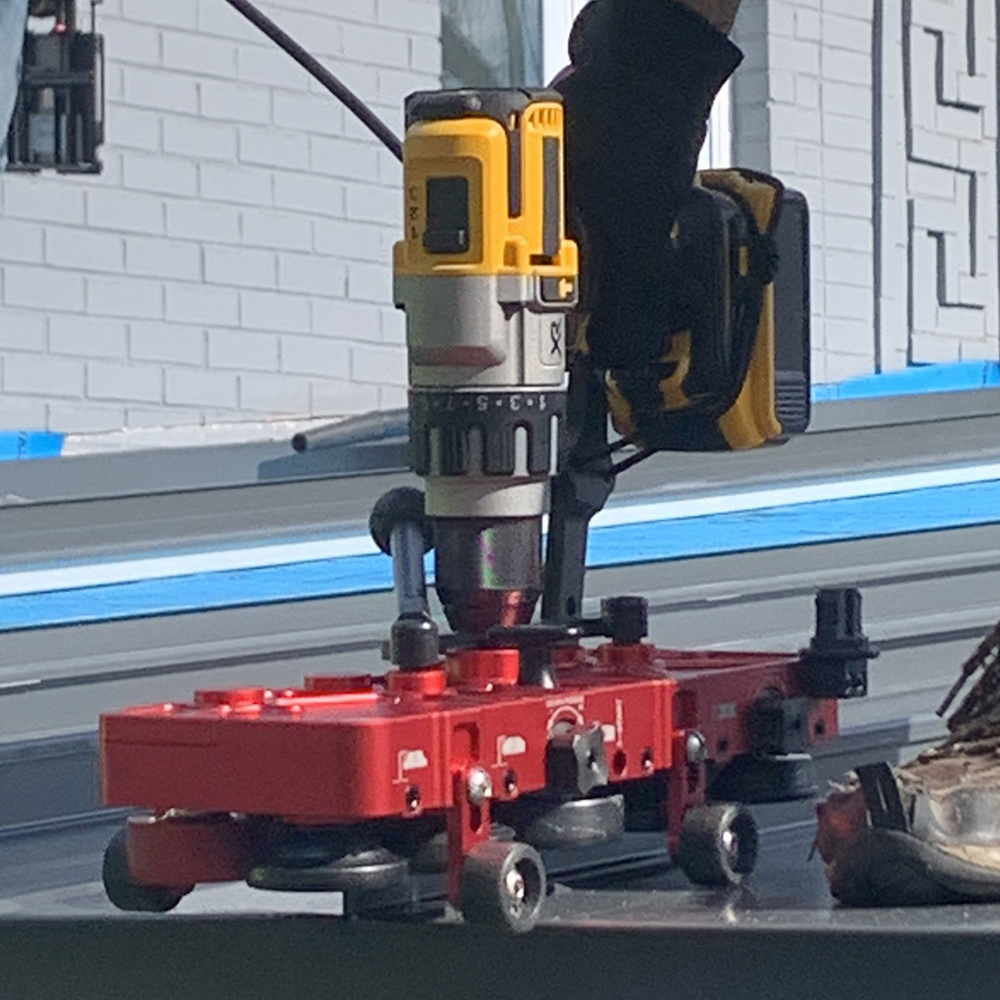

New Seamer Recognized as a METALCON Top Product

One of the newest power-assisted seamers on the market is Malco Tools, Inc.’s Power-Assisted Seamer and Cutter, which was awarded 2nd place in METALCON’s Top Product Awards in 2024. This product is ideal for effortless seaming, cutting, and removal of 1″ or 1.5″ single and/or double mechanical lock standing-seam panels efficiently. The new seamer enables the mechanical lock of standing seam panels in less time while enhancing safety and expanding the range of compatible panel profiles. The power-assisted cutter cuts below the mechanical lock and through clips with precision, allowing for quick and safe removal of standing seam panels without damaging the cutting discs.

Shane Norman, senior product manager at Malco, says, “Malco’s power-assisted seamers and cutters are the latest innovative, high-quality additions to our metal roofing portfolio, representing the fastest seaming and cutting machines on the market.”

AI and the Future of Seaming Technology

Artificial intelligence (AI) is beginning to revolutionize the world of metal roof installation by enhancing precision, efficiency, and safety. AI-powered seamers and cutters use sensors to analyze panel alignment and adjust operations in real-time, ensuring a flawless seam with minimal errors or material waste. Advanced automation allows tools to adapt to different materials and environmental conditions, while predictive maintenance features monitor performance and prevent downtime. AI innovations are not just improving productivity but also enhancing safety on job sites, paving the way for smarter, more efficient installations.

Conclusion

Seaming equipment has come a long way from manual tools to cutting-edge power-assisted machines, and now to AI-enhanced innovations. Whether you’re working with snap-lock or mechanically seamed panels, the right tools can transform the efficiency and durability of your projects. As technologies like AI continue to revolutionize the industry, the future of metal roofing installation looks brighter than ever.