When it comes to constructing energy-efficient, durable, and resilient buildings, the envelope matters. Among the most important components in a high-performance building envelope are air and vapor barriers — but while these two are often confused, they serve very different roles. Understanding their functions is key to building smarter, especially in climates where fire, moisture, and extreme weather are constant threats.

Whether you’re designing for efficiency, durability, or disaster resilience, knowing the difference between air barriers and vapor barriers—and when to use each — is critical. Let’s break it down.

What is an Air Barrier?

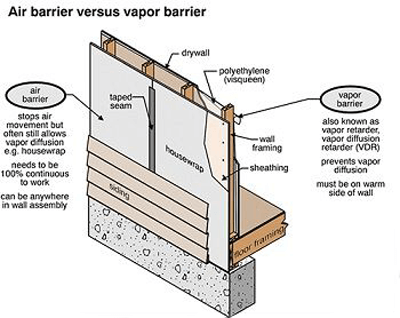

Air barriers are materials designed to control the movement of air into and out of a building’s envelope. They help prevent drafts, reduce energy loss, and improve indoor air quality by sealing off gaps, cracks, and porous materials where air can infiltrate or escape.

According to the Air Barrier Association of America (ABAA), “An “air barrier” is a combination of materials designed and installed in such a manner in order to drastically reduce or even stop the flow of air into and through the building enclosure.”

The purpose of an effective air barrier is to regulate the indoor climate by stopping the transfer of air, and the moisture associated with, between the interior and exterior of a home. An air barrier must also resist air pressure differences that act on them. Modern building codes—such as those in the International Energy Conservation Code (IECC)—often require the use of air barriers to meet airtightness standards.

Air barriers can be made from rigid materials like plywood or drywall, fluid-applied membranes, or flexible sheet membranes. The key is that they must be continuous and properly sealed at joints, seams, and penetrations.

What is a Vapor Barrier?

A vapor barrier — more accurately called a vapor retarder — is designed to slow down the movement of water vapor through building materials, rather than stop it entirely. The ABAA defines vapor retarders as “materials used to slow or reduce the movement of water vapor.” That distinction is important: vapor retarders are not impermeable shields. In fact, in many climates and wall assemblies, allowing for some level of vapor diffusion is both normal and necessary to prevent moisture from being trapped within walls.

Even the most impermeable materials can allow a small degree of vapor transmission, depending on conditions such as material tolerances, age, exposure, and imperfections in installation. This is why proper detailing and climate-specific design are essential. A vapor retarder must be correctly selected and placed to manage moisture migration without inadvertently trapping water vapor where it can condense and cause damage.

Vapor barriers are most effective in climate zones with significant seasonal temperature and humidity differences. They are typically placed on the warm side of the insulation — interior in cold climates to prevent indoor moisture from moving outward, and exterior in hot, humid climates to block outdoor humidity from entering.

A key takeaway — vapor barriers manage vapor diffusion, not air movement. For complete protection, they should work in tandem with properly installed air barriers, which control airflow — and with it, most of the vapor movement in buildings.

Key Differences Between Air Barrier vs. Vapor Barrier

Controls

Air barrier features air movement; vapor barrier — water vapor diffusion

Building Codes

Air barrier is required in most jurisdictions while vapor barrier is typically used in climate-dependent location.

Placement

Air barriers are continuous and surround an entire envelope while vapor barrier’s location varies by climate.

Materials

Air barrier utilizes membranes, sheathing, and foam board while vapor barriers typically use polyethylene, foil-faced insulation.

Purpose

Air barriers focus on energy efficiency and air quality and vapor barriers focus on moisture control.

While some materials can serve as both, most projects will require a separate approach to managing air and vapor movement.

Benefits of Air and Vapor Barriers—Including Fire Resistance

While the primary role of air and vapor barriers is environmental control, they offer several important benefits — especially as the focus is on resilient building design in fire-prone areas such as California.

- Energy Efficiency: A tight building envelope dramatically reduces energy consumption, cutting heating and cooling costs.

- Moisture Protection: Preventing air and vapor infiltration protects against mold, rot, and structural degradation.

- Indoor Comfort: Fewer drafts and more consistent humidity levels enhance occupant comfort.

- Fire Resistance: Properly installed barriers can help compartmentalize spaces and slow the spread of fire and smoke. Many high-performance air barriers are now rated for fire resistance and contribute to assemblies that meet wildland-urban interface (WUI) requirements.

- Sustainability: High-efficiency, durable buildings are not just cost-effective—they’re essential for meeting green building goals.

In California, where communities are rebuilding in the wake of devastating wildfires, these barriers are essential to constructing homes that can better withstand fire, heat, and smoke intrusion. Building codes in these areas increasingly emphasize fire-resistant construction assemblies, and continuous air and vapor barriers are part of that equation.

Choosing Between an Air Barrier vs. Vapor Barrier

The short answer? You usually need both — but the type, placement, and materials depend on the building design and regional climate.

Air barriers are a must-have. They are required by code and provide year-round energy and moisture benefits. Vapor barriers, on the other hand, are climate-specific. In hot-humid climates, vapor barriers are often used outside the insulation to keep humid air out. In cold climates, they go on the warm (interior) side to stop indoor moisture from entering wall cavities.

Both air barriers and vapor barriers, especially when combined, can also significantly impact a building’s fire resistance. Air barriers, by preventing air leakage, can reduce the potential for fire spread and oxygen supply, while vapor barriers can protect structural elements from moisture damage, which could weaken them and contribute to fire damage. NFPA 285 standards, for instance, often require fire-resistant air and vapor barrier systems as part of a total wall assembly.

The best approach is to consult building codes, understand your climate zone, and design assemblies that balance both air tightness and vapor control, without accidentally trapping moisture.

Learn More with METALCON – Online or In Person

Want to dive deeper into barrier strategies, fire-resistant construction, and the latest code requirements? METALCON has you covered.

Watch METALCON’s dynamic webinar on building fire-resistant homes, covering building science, code development, and product innovation with practical strategies you can use right now.

Presented by the Executive Director of the Air Barrier Association of America, this webinar explores how air leakage impacts energy and moisture performance in buildings, highlights the importance of whole building blower door testing, and introduces the ABAA’s technician training and certification programs.

And don’t miss METALCON 2026, happening October 7-9 in Orlando, Florida, where you’ll find hands-on education, exhibitor demos, and real-world solutions for building smarter and safer. Learn how metal construction, high-performance barriers, and resilient design are shaping the future of construction.

👉 Join us online or in person and stay ahead of the curve. Visit METALCON to register for upcoming webinars or learn more about our Las Vegas event.