Metal processing isn’t the most well-known, sexiest occupation in the world. But we love it, have a ton of expertise in it, and we are gearing up for a great show at METALCON in Atlanta!

Not everyone knows what metal folding and bending is, or the important role it plays within the architecture and roofing markets. Not everyone is trained to do it properly. Not everyone is aware of the equipment and options available. This is the situation that we all face when trying to grow a fabrication business. That’s why we need experienced partners who understand the industry, and who want to help build businesses and keep customers happy.

Competitiveness, Efficiency Gains, and Labor Availability Impact Your Business

It’s not getting any easier out there. More and more product designs are becoming commoditized. Your customers’ schedules are becoming even more demanding. It’s my privilege to speak with business owners to better understand their business needs. Not having labor on hand and control over fabrication makes it harder to satisfy customers and contractors who are on tight schedules. How do you differentiate yourself in the market? This challenge intensifies when you are trying to meet deadlines and do more for customers so you can grow your business.

A theme that keeps coming up in our conversations is the need to control your own destiny. People are telling us they want to do more themselves, so they don’t have to depend on an overwhelmed supply chain where you’re competing with dozens of others who need time like product. Taking control of more production while naturally reducing (or at least maintaining) current staff is a complex calculation, right?

One of the best ways around this issue is to invest in new machinery to reduce the reliance on outside vendors and sometimes even in-house labor. But where do you start? How do you find the team that helps get you from being reactive in the day-to-day work to being able to satisfy customer demands for increasingly accurate metal work at the cost that needs to be set.

Identifying Technology that Works for Your Unique Situation

The answer lies with investing in technology and automation so you can actually produce more product, to tighter specs, keep your customers happy, and at the same time keep your staff interested and engaged as they pick up new skills. As an independent distributor, MetalForming LLC can help you sort through the issues and provide a great solution from amongst a set of “best in class” suppliers for metal bending, roll forming, and coil processing.

At MetalForming, we work with everyone from roofing contractors to major architecture product fabricators producing some crazy designs someone behind a desk dreamed up. The people who handle our business here take our “One Partner. Trusted Expert.” claim to heart. Every business has its unique needs, and when you work with eight world-class brands in every facet of sheet metal production like we do, you can bring a lot of super flexible solutions and ideas to the table at different price points and capabilities.

In the more than 25 years that MetalForming has been in business, we’ve been working with some of the best equipment manufacturers in Europe who have, frankly, been driving the industry forward in terms of functionality and automation. We’ve brought new lines like Schechtl, Schlebach, Schröder, and Jorns to the North American market, advancing our customer’s ability to service the end customers, and grow their businesses.

Being a preferred partner and an expert means much more to MetalForming than handling equipment. We believe that when you make the “big decision” to invest in new equipment, you need the people to support that equipment. We support customers through set-up, ongoing maintenance agreements to keep the machines up and running, training, and field service. At MetalForming, our service and technical support team trains with our manufacturers, getting the latest in tips and tricks for maintaining and upgrading the machines for best efficiencies and functionality. When we focus on the helping you identify the machinery that you need for your situation, then provide the training and support to keep it running efficiently, you can focus on your company and your customers, with the confidence that we have your back.

What’s on tap at METALCON in Booth #923

We are super-excited to have METALCON in our backyard this year. The show is in Atlanta, the self-proclaimed birthplace to all things metal folding, and we’re just 30 minutes away in Peachtree City. When you come to the show, you’ll be able to meet more of our experts in MetalForming’s Booth #923 – many of whom have 20-30 years’ experience in the business and have seen it all.

Plus, we’re bringing some phenomenal new machines to METALCON this year. All our manufacturers have upgraded their machines this year with new functionality that helps companies make the move to a more automated and efficient job shop.

Schröder: I’m going with the Schröder brand first, because we have a cool promotion/challenge for anyone coming to the show. The Schröder PowerBend Multi(PBM) bender literally has no equivalent. It is simply the most flexible thin gauge folder on the market today. It sits at the intersection of precision and architecture fabrication, and is flexible enough to take on the challenges that designers and architects throw your way. We haven’t found a design yet that this machine couldn’t build.

So here’s the challenge: bring us your sketches or your designs, and we’ll figure out how the PBM can make it. If you can stump the machine, we’ll give you a bright orange Yeti cup, and provide you with our design feedback.

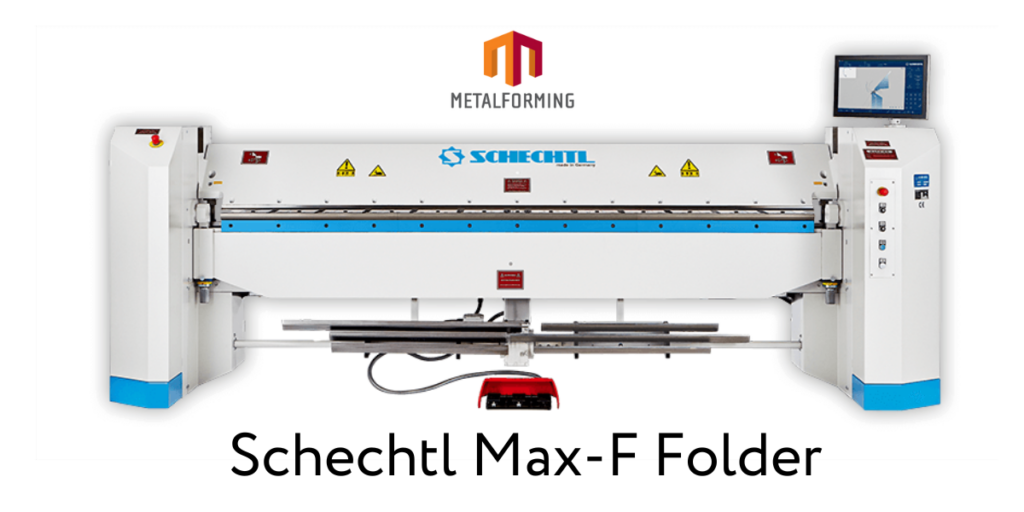

Schechtl: The Schechtl MAX is the single most popular selling folder in North America. We’ll have the Schechtl Max-F in the booth to demonstrate the benefits of its F-geometry. This is a rock-solid, work horse that is designed to give you 20 years of payback. These machines are designed to be upgradeable, as new technology comes into play. In fact, we have some older machines in our workshop today in Peachtree City today that our team is refurbishing with new retrofittable control cabinets and new software to give them a longer life. While you are at the booth, be sure to take look at this machine. If you already have one in your shop, let’s talk about leveling up your machine for the next ten years.

Jorns: We’re bringing the Jorn’s Double Bender (JDB) to METALCON this year. It’s a fantastic piece of flexible technology, which allows you to build more challenging, less commoditized parts. The modular design allows you to start small and add more automation as your business grows. The JDB does the work efficiently, with upper and lower bending beams, which eliminates extra handling. Your operator can quickly learn the machine’s intuitive software and you’ll be up and running. (Photo: Jorns Double Bender)

Stolarczyk: We can’t have a discussion about architectural fabrication without talking about our coil processing partners Stolarczyk, Krasser and Schlebach. Unfortunately, we cannot bring everything we offer to the show, but we love the range of versatility these suppliers offer for coil processing.

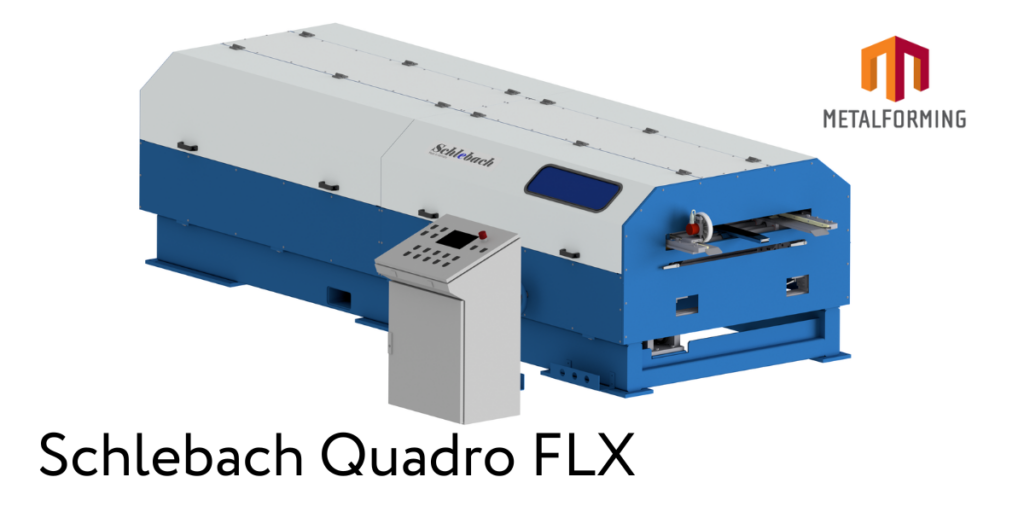

From decoiling, recoiling, slit-to-width, cut-to-length, blanking, automatic knife changes, and full coil farms, these machines have it all. By having several lines to choose from, our customers can select exactly what they need for today, and into the next five and even ten years. Our diverse selection of equipment options helps you manage your materials from uncoiling to recoiling, and creating a less labor-intensive process for you and your team. Stop by Booth 923 to see the Stolarczyk decoiler, the ST 1250 slit/cut to length and blanking machine, and the Schlebach Slasher. We can discuss how it can make your work life easier.

Schlebach: We’re bringing several Schlebach machines to the show, so you can see just how this fantastic brand can help you build a flexible shop that can drive efficiency. If you are looking at new machines for roll forming, slitting, seaming, curving and hemming, this brand is a great one to evaluate for its versatility, strength, and functionality

One Partner. Trusted Expert.

MetalForming, LLC provides the equipment, technology, knowledge, and support that you need to differentiate your sheet metal processing business, whether you are operating in the Architectural or Precision market space. This isn’t the proverbial “world’s best cup of coffee”. We have a proven history and track record second to none.

As the largest distributor of sheet metal processing machines in North America, we support your operations with the people, equipment, technology, and service to satisfy your customers and build your brand. We consult with business owners to scope out the right machine options and functionality, to ensure that they get what they need to thrive.

We provide folders, handbrakes, roll forming, coil processing, shears, storage & materials handling equipment. Our consulting services help you with machine retrofits and of course, we have expert customer service, field service and training.

MetalForming is located near the Atlanta airport on a five-acre campus made up of three buildings which include administration and sales offices, technical support, customer service, field service, parts support, product demonstration showroom, training facility, machine refurbishment, and warehouse space that stocks ready-to-ship machines and spare parts.

Metalforming-usa.com | 770-631-0002

by Stephen Gosk, President & CEO

MetalForming, LLC