While steel structures are known for their durability, affordability, and low maintenance, the planning process needs to be just as solid as the structure itself. Design mistakes are common, but with proper planning, most are avoidable. In this post, we’ll highlight some of these mistakes, why they matter for metal buildings, and how METALCON can help. METALCON offers year-round resources and education — along with its annual event — to help the metal construction industry design and construct metal buildings that stand the test of time.

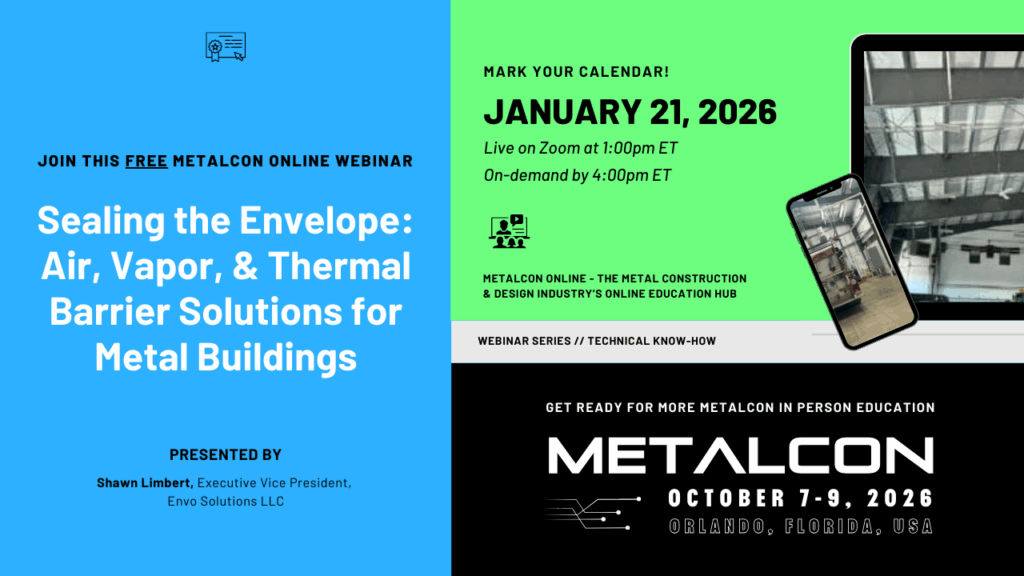

Speaking of timing … you’re in luck — METALCON Online’s next free webinar, Sealing the Envelope: Air, Vapor, & Thermal Barrier Solutions for Metal Buildings, provides tools to help avoid design mistakes specifically relating to insulation, ventilation, and envelope planning. Read on to learn more.

What Are Some Top Structural Design Mistakes in Metal Building Construction?

Skipping Critical Site Prep & Foundation Coordination

Failing to properly prepare the site — including grading, drainage, soil compaction, and geotechnical testing — can lead to uneven settlement, water issues, and foundation stress over time. Likewise, poor coordination between foundation design and steel anchor bolt placement often results in costly field adjustments.

Why it matters: Metal building systems rely on precise tolerances and predictable load transfer through steel frames and anchor bolts. Inadequate site preparation or poor foundation coordination can compromise column alignment, create connection stress, and affect the performance of metal panels and cladding systems.

Ignoring Permits, Codes & Local Load Requirements

Designs that don’t fully reflect local building codes — particularly snow, wind, and seismic loads — or move forward without proper permits risk failed inspections, project delays, redesigns, or unsafe conditions.

Why it matters: Metal buildings are engineered systems designed to resist local wind, snow, and seismic loads. Failing to account for code requirements can lead to under-designed frames and overstressed connections, reducing the building’s resilience to extreme weather or long-term service demands. With resilience top of mind across the industry, ensuring code-compliant design protects both structural performance and occupant safety.

Choosing the Wrong Building Type for Use & Future Needs

Selecting a generic or under-designed building for its intended function — such as planning a basic structure when heavy equipment use or future expansion is likely — is a common early-stage misstep.

Why it matters: Metal building type directly impacts bay spacing, clear-span capabilities, framing depth, and load capacity. Selecting the wrong system can limit crane integration, mezzanine support, equipment loads, and future expansion — ultimately compromising the building’s resilience to evolving operational demands and extreme conditions.

Overlooking Insulation and Ventilation in Structural Design

Metal building envelopes require thoughtful integration of insulation and ventilation to prevent condensation, heat buildup, corrosion, and moisture-related structural issues. Poorly designed ventilation can trap hot, humid air, leading to interior condensation and long-term damage to steel framing and coatings.

Why it matters: Designing the envelope isn’t just about comfort — it protects the structure. In metal buildings, poorly designed insulation and ventilation systems can lead to condensation on steel framing, corrosion of metal panels and fasteners, and reduced roof and wall system lifespan. A well-designed envelope protects structural steel while improving energy performance.

Working with the Wrong Steel Building Provider

Not all steel building providers offer the same level of engineering expertise, material quality, or project support. Choosing a supplier based solely on price — without fully vetting credentials and capabilities — can result in structural shortcomings, missed timelines, and costly surprises during construction.

Why it matters: Metal buildings depend on integrated engineering, fabrication, and erection coordination. Working with an inexperienced or underqualified provider can result in incomplete engineering, incompatible components, and systems that struggle to meet performance, code, and durability expectations.

How Do You Properly Plan a Metal Building Layout Before Construction Begins?

Proper planning starts with understanding how the building will be used — not just on day one, but throughout its lifecycle. A well-planned metal building layout balances structural requirements, operational efficiency, and future flexibility, helping to prevent many of the design mistakes outlined above.

Key considerations include:

Define the building’s purpose and workflow.

Start by identifying how the space will function day to day. Equipment placement, vehicle traffic, storage needs, and personnel flow all influence column spacing, clear heights, door locations, and floor loading requirements.

Account for current and future loads.

Rooftop equipment, cranes, mezzanines, solar panels, and future expansions should be factored into the structural design early — not added as afterthoughts.

Evaluate site conditions and orientation.

The building’s placement on the site affects drainage, access points, prevailing winds, snow drifting, and solar exposure. Soil conditions and bearing capacity directly influence foundation design and long-term structural performance, while orientation decisions can also impact ventilation strategies and energy efficiency.

Plan the building envelope early.

Insulation, ventilation, vapor control, and air sealing should be coordinated during layout planning to avoid conflicts with framing, penetrations, and mechanical systems later.

Coordinate early with qualified professionals.

Engaging experienced designers, engineers, and suppliers early helps ensure layout decisions align with code requirements, constructability, and long-term performance.

Explore Tools and Technologies That Simplify Metal Building Design with METALCON

In today’s building climate — marked by evolving codes, performance expectations, and increasing demands for resilience — proactively using the right tools and resources is critical to avoiding costly metal building design mistakes. METALCON connects the metal construction community with the education, expertise, and technologies needed to design smarter, more resilient buildings.

At METALCON — both year-round and at the annual event — professionals can access:

- METALCON Online, featuring an expansive library of free webinars covering Business Strategies, Technical Know-How, Sustainability & Efficiency, Metal Construction News, and Recorded In-Person Sessions — all designed to help teams stay informed and avoid common design and planning pitfalls.

- Design and engineering tools and technologies showcased by leading manufacturers and solution providers, supporting better decisions around layout planning, load considerations, and building envelope performance.

- The Design District @ METALCON, a dedicated destination for architects, designers, specifiers, and engineers who are shaping the future of the built environment through innovative materials, systems, and approaches.

- Expert-led education and peer learning, including live sessions, webinars, and case studies that address real-world challenges such as code compliance, envelope design, sustainability, and long-term building performance.

- Unmatched industry connectivity, linking attendees with more than 15 industry partner associations and 20+ publication partners, providing trusted insights, standards, and perspectives from across the metal construction ecosystem.

Want to dive deeper into envelope performance? Join METALCON Online LIVE on January 21 for Sealing the Envelope: Air, Vapor, & Thermal Barrier Solutions for Metal Buildings. In this webinar, Shawn Limbert of Envo Solutions LLC explores how air, vapor, and thermal barrier systems impact energy efficiency, code compliance, and long-term durability in metal buildings. Attend live for the opportunity to interact with the speaker, or watch on demand at your convenience.

In today’s fast-paced and ever-changing building climate, proactively using the right tools and resources is more important than ever. By planning carefully and leveraging METALCON’s education, expert guidance, and technology, you can avoid common structural design mistakes, streamline your metal building layout, and ensure your projects meet performance, energy, and durability expectations. Today’s blog isn’t just a guide — it’s a reminder that thoughtful planning and the right support make all the difference in delivering metal buildings that stand the test of time.