The U.S. non‑residential building construction market continues to expand, driven heavily by manufacturing, warehouses, and data centers. In 2024, over 27 % of all non‑residential construction spending was in manufacturing projects, while warehouses represented 7 %, and data centers about 3 % of non‑residential spending. That sector—manufacturing, warehouses, and data centers—has shaped overall trends in 2024. (Read more: ConstructConnect)

More broadly, the U.S. industrial building construction market (which includes manufacturing facilities as well as warehouses and logistics centers) was valued at about US $43.8 billion in 2024, and is projected to grow to US $61.6 billion by 2032, at a CAGR of 4.5 % (read more).

Within the U.S. pre‑engineered metal building market, the manufacturing application segment alone accounted for 33.8 % of total revenue in 2023, making it the single largest application category — and it’s projected to grow at the fastest rate through 2030.

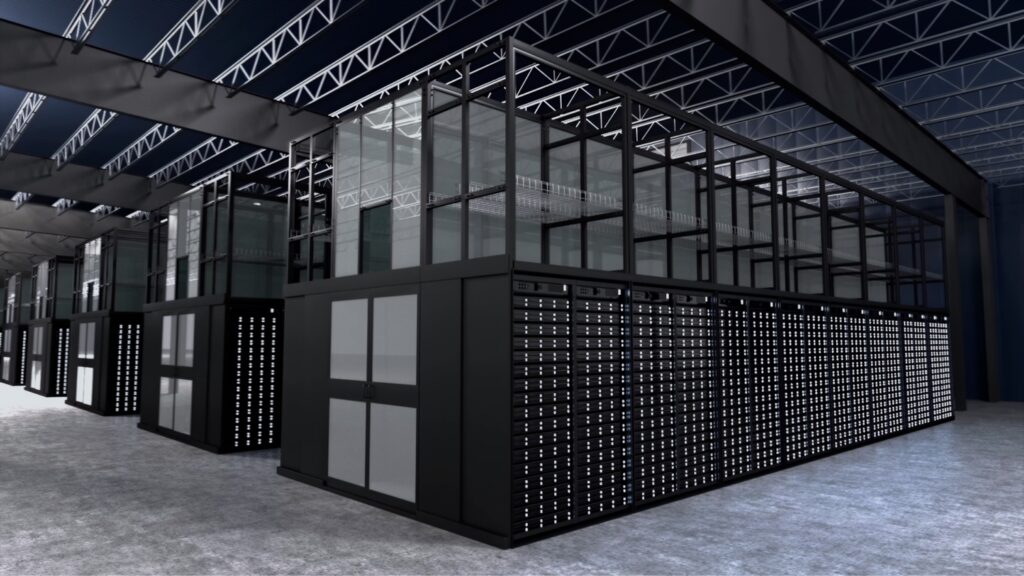

The big picture? Manufacturing facilities — including warehouses and data centers — are driving a surge in new construction demand. Fueled by the rapid growth of cloud computing, artificial intelligence, and data-driven applications, data center construction is expanding at an unprecedented pace. Across all segments, metal building systems are becoming the go-to solution, offering speed, scalability, and long-term performance.

3 Key Benefits of Using Metal (Steel) Buildings for Manufacturing Facilities

Speed & Cost Efficiency

Pre‑engineered metal buildings are prefabricated off‑site and assembled quickly on‑site. Compared to traditional construction, this modular approach significantly reduces construction time and labor costs. For example, Costco reportedly builds its metal warehouse stores in about 110 days, compared with 160–180 days for conventional construction.

Parallel off‑site fabrication and foundation work allows projects to proceed faster and more efficiently—which helps manufacturers reduce downtime and online sooner. CDMG, one of the nation’s foremost engineering companies serving industrial markets, adds, “Prefabricated metal buildings are built in a warehouse, so you don’t have to worry about any rain delays. And because there are fewer framing pieces needed, overall construction will be quicker.. The parts of your metal building will be delivered to the job site ready to assemble.”

Structural Flexibility, Durability & Scalability

Steel is inherently robust and highly adaptable:

- It doesn’t warp, bend, twist or buckle, and it holds tight tolerances—making it easy to modify, expand, or reconfigure internal layouts as needs change

- Clear‑span framing allows large, column‑free interior spaces—critical for layouts with heavy machinery, production lines, or future expansion.

- Pre‑engineered systems can be tailored precisely: high ceilings, specific load‑bearing capacities, insulation, doors, windows, clerestories, and more.

- Steel buildings offer low maintenance and long service life, and costs tend to stay stable relative to fluctuating materials like wood or concrete.

Sustainability, Energy Efficiency & Long‑Term ROI

Steel is a highly sustainable material:

- It is 100 % recyclable, often made with significant recycled content, reducing lifecycle environmental impact.

- Steel buildings also lower construction waste, reduce energy costs, and they last for decades, making steel one of the most environmentally friendly building materials.

- The deep wall cavities of metal building systems leave room for thicker insulation. That insulation could shrink your energy expenses by 50%, especially if you live in an area with extreme heat or cold.

Furthermore, as emphasized by Nucor, steel buildings bring sustainable benefits to data center construction — including durability under heavy loads, fire resistance, thermal performance, and lifecycle value — and these advantages carry over directly to manufacturing facilities as well. With the shift of warehouse operators into data center development, it underlines the convergence of industrial infrastructure needs — often built using pre‑engineered metal systems.

In Summary

- The manufacturing construction sector stands as the largest and fastest‑growing component of industrial building spend in the U.S., accounting for over 27 % of non‑residential investment in 2024.

- Metal building systems — especially pre‑engineered steel structures — are meeting that demand head‑on, with nearly 34 % market share in the U.S. manufacturing application segment.

- The top advantages — speed, flexibility & durability, and sustainability with long‑term ROI —make metal buildings ideal for manufacturing facilities seeking reliability, scalability, and efficiency.

Stay Current on Metal Building Construction at METALCON

Would you like to stay at the forefront of metal building trends and innovations? METALCON offers two powerful ways to engage:

Online education year‑round: Access webinars, design tools, recorded presentations, and technical resources. Join us for free at our next event, August 6 — Metal Contractors Share the Real Deal — presented MetalCoffeeShop (MCS) and METALCON as we bring a leading group of metal contractors to talk about the state of the metal industry.

Attend the annual event in person, taking place October 21–23 this year in Las Vegas—a must‑attend conference and trade show for professionals working in metal construction, including manufacturing and industrial facility design and construction.

Join industry leaders, explore cutting‑edge materials and methods, and build your knowledge in metal building systems for manufacturing.