From ancient times when blacksmiths were forging weapons to modern-day fabricators shaping skyscrapers, metalworking remains a vital aspect of our industrial and every-day landscape. At the heart of this work lies the essential tools that transform raw materials into amazing creations. As we delve into the world of metalworking, let’s explore the indispensable tools that every craftsman should have in their “toolbox.”

Metal Cutting Bandsaw

When it comes to cutting metal stock with precision and efficiency, a metal cutting bandsaw is an indispensable tool. Its vertical blade allows for straight and curved cuts, making it ideal for a wide range of metalworking applications. Bandsaws come in a variety of sizes and metal workers commonly use it to help cut curves and irregular shapes. Bandsaws are versatile and a great starting point for beginners.

Drill Press

Precision drilling is critical in metalworking, and a drill press provides the stability and accuracy needed for consistent results. This machine is designed to remain stationary or in a fixed position. It typically sits on a fixed stand and is used for drilling holes in various materials accurately. From creating holes for fasteners to tapping threads, a quality drill press is indispensable for various metalworking tasks. Drill presses are needed for a variety of reasons but the main purpose and need is for simply accuracy.

Welding Machine

A cornerstone of metalworking, the welding machine joins metals together through the application of heat and pressure. Whether you’re fabricating a sculpture or constructing a building, a reliable welding machine is essential for fusing metal pieces seamlessly.

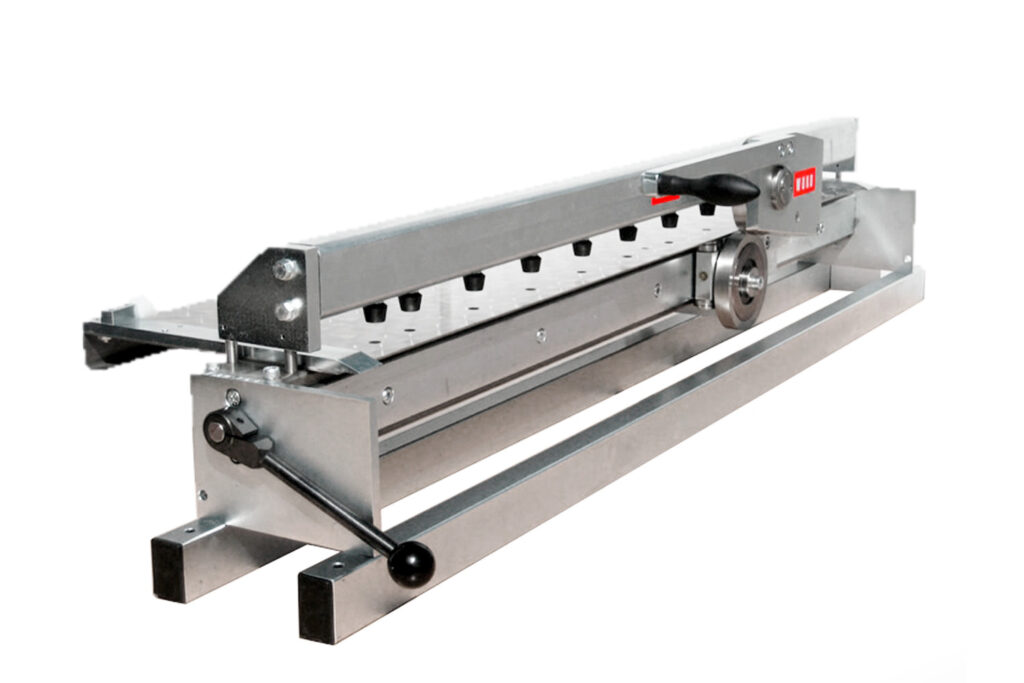

Sheet Metal Shears

When it comes to cutting large sheets of metal with speed and accuracy, a sheet metal shear is the tool of choice. Also known as die cutting, metal shearing is the process of cutting straight lines on a metal die or stock by forcing two blades past each other. The metal shearing process is similar to how scissors work except all points along the edges of both blades meet at the same time. From roofing panels to automotive bodywork, a shear simplifies the cutting process and ensures clean, precise edges.

Metal Working Lathe

More of a specialty tool, a lathe is used for turning cylindrical workpieces and creating intricate designs. The most common uses of a lathe are for turning down (removing material) outside diameter of a round tube, rod, or other pieces of metal to make it concentric. Other uses include counterboring, facing, drilling, tapering, threading, and shaping. A lathe isn’t considered a necessity, but good to have if you are carving out your own niche in metal fabrication.

Angle Grinder

Versatile and powerful, the angle grinder is another must-have tool for any metalworker. Its rotating abrasive disc can cut, grind, and polish metal surfaces with precision and efficiency, making it indispensable for shaping and finishing projects. This can include anything from grinding wheels to abrasives. The most common grinders and disc consist of cutoff wheels or flap disc. In most applications, your grinders and disc will be used for finishing a project and can be used for wire wheels.

Safety Gear

Safety gear is essential for protecting oneself in the metalworking environment. From welding helmets to heat-resistant gloves, investing in high-quality safety equipment is crucial for preventing accidents. For example, if you are welding, you should consider investing in an auto-darkening helmet, not only to protect your eyes from the glare but also to protect your face in general.

See Metalworking Tools at METALCON

While the list of metalworking tools above is by no means exhaustive, exhibitors from around the world will gather at METALCON 2025, October 21 – 23, 2025 in Las Vegas, to showcase the latest advancements in metalworking technology and equipment. A wide array of these essential metalworking tools will be on display in their booths, offering attendees the opportunity to explore firsthand the cutting-edge innovations shaping the industry. From state-of-the-art roll forming machines to precision drill presses, cutters to benders, sealants to fasteners — visitors to the show will have the chance to interact with leading manufacturers and suppliers, gaining valuable insights into the capabilities and features of the tools that are advancing the industry.

Whether you’re looking to upgrade your workshop or simply stay abreast of the latest industry trends, METALCON provides a unique platform to discover the essential tools that are driving innovation in metal construction.

METALCON Top Product Awards 2025

Now in its fifth year, this awards program recognizes companies at the forefront of innovation in industry products, technologies and solutions. METALCON exhibitors are invited to submit nominations for their standout metal products across 15 categories, from walls and roofs to contractor tools and equipment, paint and coatings to roll forming equipment and more. To be eligible for consideration, a product must have been introduced to the market after Jan. 1, 2024, and its manufacturer must be a participating exhibitor at METALCON 2025. All nominees showcase their top products with special product recognition at their booths in Las Vegas and the top three award winning products will be announced on October 22. Submission deadline is August 8, 2025.

Check out last year’s winners and click HERE to read more about this year’s program details and how to nominate a product.