As the construction industry wraps up 2025 and looks toward a new year, one message is coming through clearly from global leaders and technology innovators alike: the way we design, build, and operate buildings must fundamentally evolve.

In April, Cristina Gamboa, World Green Building Council CEO, shared her vision in Blueprint for Change: A Strategy to Transform Buildings and the World They Shape, outlining how the built environment must drive decarbonization, resilience, and long-term economic value. More recently, Intelligent Build.tech explored similar themes in Built for Change: The Five Global Forces Shaping the Future of Every Building, pointing to urbanization, electrification, digitalization, labor constraints, and sustainability as the pressures reshaping construction.

While these perspectives come from different angles — one strategic and policy-focused, the other technology and operations driven — they draw on the same conclusion: buildings must be smarter, more resilient, lower-carbon, and easier to deliver at scale.

Against that backdrop, metal construction is poised to serve not as a specialty solution, but as a practical response to what the building world is saying it needs next.

Building Smarter in a Changing World

View the Case Study

Both articles emphasize that buildings are no longer standalone, passive structures. They are becoming active systems — connected to energy grids, digital platforms, and changing occupant needs — while also being expected to withstand stronger climate events, workforce shortages, and economic uncertainty.

To meet the current and future demands, materials and construction methods must evolve as well. Metal construction aligns closely with these emerging priorities, helping builders respond to global forces without reinventing their entire approach.

Why More Builders are Incorporating Metal in Construction Projects

1. Metal Supports Decarbonization and Climate Action

The World Green Building Council makes it clear: transforming the built environment is essential to meeting global climate goals. Moving forward, reducing both operational and embodied carbon is no longer optional — it’s paramount.

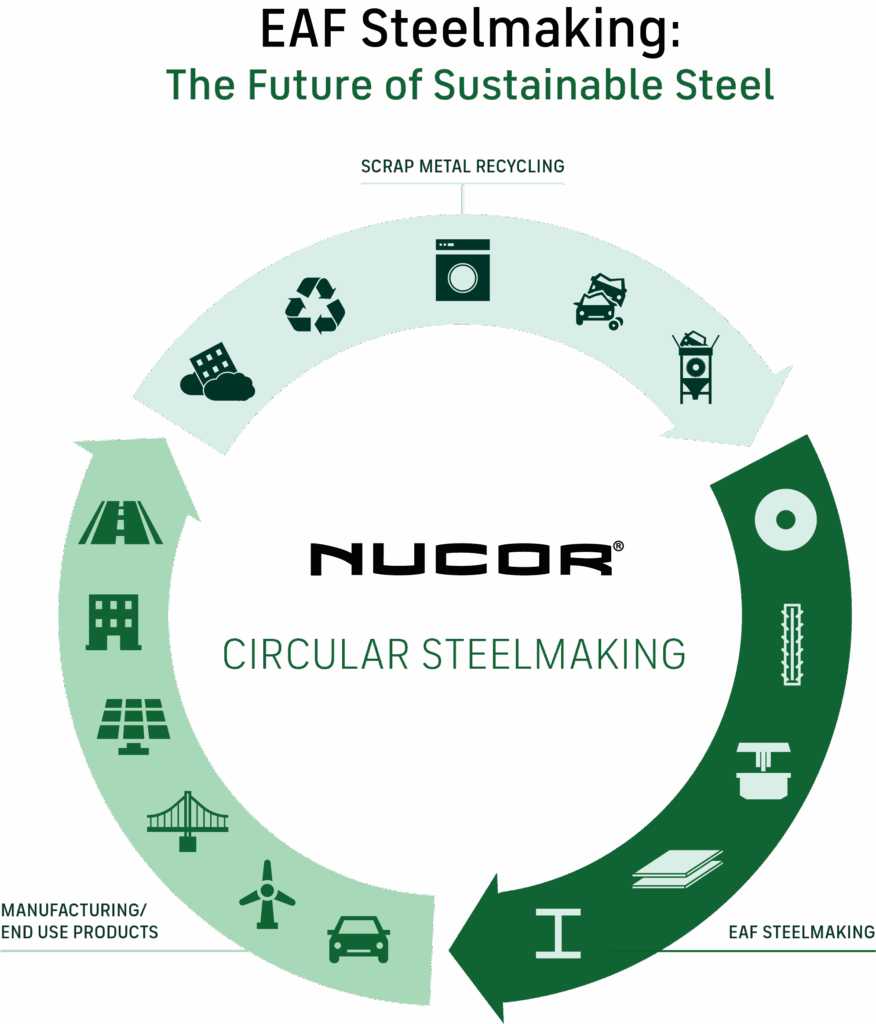

Metal construction supports this shift in several ways. Steel and aluminum are among the most recycled materials in the world, with high recycled content already common across many applications. Continued growth in electric arc furnace (EAF) steelmaking, renewable-powered production, and transparent environmental product declarations (EPDs) is further reducing embodied carbon impacts.

From energy-efficient building envelopes to cool metal roofing and compatibility with electrified building systems, metal helps builders deliver on the climate expectations outlined in the Blueprint for Change.

2. Built-In Resilience for a Riskier Future

Resilience is another major theme shared across both articles. As climate risks intensify and weather events grow more extreme, buildings must be designed to endure — not just meet minimum code.

Metal’s strength, durability, and noncombustibility make it well suited for this reality. High strength-to-weight ratios perform well in areas susceptible to seismic activity, while metal systems offer strong resistance to wind, fire, pests, and moisture-related degradation. Longer service life and reduced maintenance needs also support the kind of lifecycle resilience emphasized by global building leaders.

Metal stands as the leading choice for buildings stay operational, insurable, and valuable in an increasingly unpredictable world.

3. A Proven Path to Circular Construction

The WorldGBC strategy places strong emphasis on circular economy principles — moving away from “build, use, discard” toward systems that retain value over time.

Metal construction already operates within this model. Structural steel, metal panels, and framing systems are routinely recovered and recycled at the end of a building’s life, often without loss of performance. Many components are also well suited for reuse, adaptation, or future disassembly.

Prefabricated metal systems further reduce jobsite waste and improve material efficiency, directly supporting circular construction goals while helping builders meet evolving sustainability expectations. Read more about prefab metal systems in our recent blog post, “2025 in Review: A Defining Year for Metal Construction.”

4. Speed, Precision, and Labor Efficiency

In Built for Change, Intelligent Build.tech highlights labor shortages and demographic shifts as one of the five global forces shaping every building’s future. That pressure is already being felt across construction markets.

Metal construction helps address these challenges through off-site fabrication, prefabrication, and precision manufacturing. These approaches improve quality control, shorten project timelines, and reduce dependence on scarce skilled labor in the field.

Metal systems also integrate seamlessly with digital workflows — including BIM, automated fabrication, and increasingly, AI-driven planning and building operations. As buildings become smarter, metal provides a reliable, efficient backbone for modern construction.

5. Scalable Solutions That Make Economic Sense

One thing both articles make clear is that the industry can’t rely on small test projects or one-off ideas anymore. Real progress depends on solutions that can be used again and again, across many types of buildings and markets.

Metal construction excels here. Its adaptability across commercial, industrial, institutional, and mixed-use projects makes it a repeatable solution for builders, developers, and owners alike. Predictable performance, durability, and speed help control costs while meeting rising expectations around sustainability and resilience.

As the WorldGBC describes, meaningful transformation requires an “ambition loop” between policy, industry leadership, and investment. Metal helps close that loop by turning big-picture goals into plausible and buildable reality.

More Metal, More Possibilities

As the industry looks ahead to a new year shaped by climate pressures, evolving technology, and rising expectations, one thing is clear: the materials we choose matter more than ever. The same global forces outlined by building leaders and technology experts are driving a shift toward construction approaches that are smarter, stronger, and more adaptable.

That’s why more builders are finding five powerful reasons to incorporate more metal into their construction builds— from supporting decarbonization goals and circular construction, to delivering resilience, speed, and scalable performance. Metal isn’t just keeping pace with where the industry is headed; it’s leading it.

For those looking to better understand how metal construction fits into this changing landscape, METALCON remains a vital resource. As the largest global event dedicated to metal construction, METALCON brings together the ideas, innovations, and experts shaping what comes next — from advanced materials and fabrication to smarter building systems and sustainability strategies. Beyond the annual show, METALCON Online extends that value year-round, offering ongoing education, industry insights, and access to expert perspectives that help professionals stay informed and ahead of emerging trends.

As we move into the new year, one message stands out: more metal means more possibilities — for better buildings, stronger projects, and a more resilient built environment.