The global metal roofing industry has an estimated market size of around $19 billion in 2023 and is projected to reach approximately $28 billion by 2030. This growth is driven by the increasing demand for durable, energy-efficient, and sustainable roofing solutions, particularly in residential and commercial sectors across various regions, including North America, Europe, and Asia-Pacific.

The roofing industry, like many other construction sectors, is constantly evolving with new technologies and innovations designed to increase efficiency and reduce labor costs. As labor shortages continue to challenge the construction industry, roofing professionals are increasingly turning to labor-saving products to stay competitive and deliver high-quality work. Let’s take a look at how the latest innovations are redefining and unlocking efficiencies in the roofing industry.

Current State of Roofing Tools

We’ve come a long way since the introduction of the roofing nailer in the 1950s. Today, roofing professionals have access to a variety of tools that make their jobs easier, safer, and more efficient. Some of the popular tools in the current landscape include cordless nail guns, roofing safety equipment, digital measuring devices, and roofing software. What does the future hold? As the construction and roofing industry welcomes technological changes, the newest innovations in roofing tools promise to improve the efficiency and accuracy of roofers’ work, transform the processes, and raise the industry to new heights.

Top Roofing Innovations

From advanced drone technology for roof inspections to augmented reality applications for design and planning, the next wave of advancements are raising the bar for efficiency, safety, and quality in roofing projects. Some of these labor-saving products include:

Drones for Roof Inspections

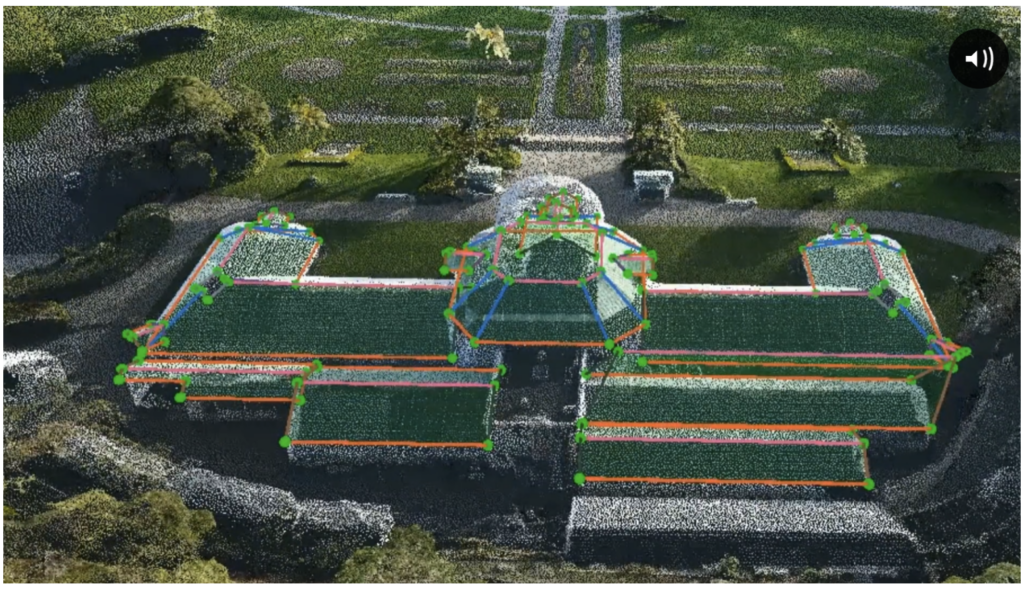

The utilization of drones in roof inspections will become more prominent, allowing for efficient data capture, high-resolution aerial images, and improved safety as roofers spend less time on potentially hazardous rooftops.

Robotic Roofing Tools

The integration of robotics is expected to revolutionize the installation, repair, and maintenance process. Robotic tools can reduce human labor, enhance precision, and provide more consistent quality. Examples include robotic nailers and shingle placement machines, which are likely to become common in the industry. Robotic tools and automated machines can perform repetitive tasks, reduce the physical strain on workers, and complete dangerous jobs that would otherwise put humans at risk.

Artificial Intelligence (AI) for Design, Estimation, and Preventive Maintenance

AI-based software is expected to play a crucial role in 3D modeling and the design process, providing accurate estimates for labor and material costs, as well as improving energy efficiency and overall roof design to meet industry standards with minimal error.

AI is also changing the game for roof maintenance. It uses data to predict when a roof might need work. This means less guesswork and fewer surprises. Contractors can spot problems before they get big, thanks to AI’s smart analysis. Drones fly over roofs collecting data that AI analyzes quickly, saving roofing contractors time and labor before small issues become larger ones.

Smart Roofing Tools

IoT technologies are revolutionizing how roofs are monitored, maintained, and managed. These advancements include leak detection sensors that provide early warnings to prevent water damage, environmental monitoring devices that track conditions affecting roofs, and structural health monitoring systems for early detection of potential issues.

Energy management tools optimize the performance of solar roofing systems, while thermal imaging and insulation monitoring identify areas for improving energy efficiency.

Advanced Materials and Sustainable Roofing Solutions

The latest eco-friendly roofing materials are not just good for the planet; they’re also cost-effective and long-lasting. Contractors can now access various options, from recycled to bio-based materials, that reduce environmental impact without sacrificing quality. Innovations in solar shingles, green roof systems, self-healing roofs, and insulation materials will continue to rise as a response to this demand.

One such company introducing labor-saving insulation products is Hunter Panels, a leader in thermal efficient polyiso insulation for roof and wall applications since 1997. In a RoofersCoffeeShop Coffee Conversation episode, Heidi Ellsworth discusses some of their newest labor-saving products with company representatives, Wesley Sherrer, Senior Manager for Product Management of Insulation, and Tom Rhoads, Western Regional Manager. They explain that today’s labor shortage is what’s fueling their company’s product innovations. Tom shared, “I read a report recently that said there were 9.4 million jobs available jobs but only 6.3 million workers to fill the jobs; an aging workforce and declining birthrates are indicators that the labor issue isn’t going away.”

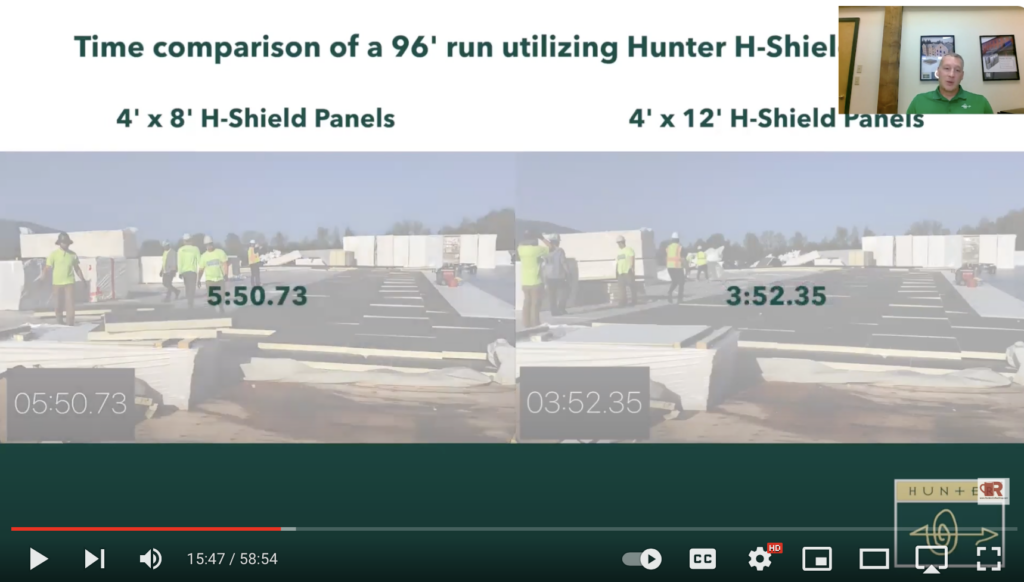

Their latest product innovations include ReadyFlash, a technology now standard with their HD panels, which provides two different colors on the sides to help contractors speed up or slow down the adhesive process. Another product just coming to launch is 4′ x 12′ H-Shield Panels, created based on field time trials. By using the larger size panels, it created a labor savings of 34%!

Watch the time lapse trial here: https://youtu.be/dFARuPny6Ek?si=4_pmAlA-G3iWON9t

Why Attend METALCON as a Roofer or Roofing Contractor?

Given the rapid advancements and the introduction of labor-saving products in the roofing industry, it is crucial for roofers and roofing contractors to stay informed about the latest trends and innovations.

Where can roofers see, touch and learn about all of these products under ONE ROOF?

Roofers can visit directly with exhibitors, learn from industry experts in free education sessions, live demos, and immersive workshops (additional fee). Learn more:

Immersive Workshop and Certification Courses

Low Slope Detailing Workshop – Certificate Course

This workshop offers a comprehensive introduction to the basics and unique details of low slope metal roofing. Attendees will learn how sheet metal can be innovatively used on low slope roofs, contrasting with the techniques required for steep roofs, and explore various creative installation options.

Metal Roofing from A (Aluminum) to Z (Zinc)

Learn from one of the industry’s finest! Metal Construction Hall of Famer, Rob Haddock, the CEO and Founder of S-5 presents Metal Roofing 101, a comprehensive course covering everything from the history of metal roofing to fabrication and manufacturing techniques.

Metal Roof Installation Training Certificate Program Parts 1 and 2

This two-day, eight-hour introductory certificate program, based on the MCA’s Metal Roof Installation Manual, offers participants classroom training on various topics, including substrates, safety, and panel types, along with direct interaction with industry experts. Successful participants will receive the MCA’s Metal Roofing Certificate of Completion.

While these workshops are not included in your registration, as a roofer or roofing contractor, you will find these incredibly valuable.

Live Hands-on Learning

METALCON’s Metal Mastery Clinics will feature a series of clinics and demos with experts from the Metal Construction Association and the Metal Roofing Alliance. They plan to discuss industry best practices for Standing Seam Metal Panels, Preformed Painted Metal Shingle, Soldering Techniques for Architectural Sheet Copper, Retrofit Systems with Metal Roofing, Prefinished Metal Panels; and Stone Coated Metal Panels.

METALCON’s Training Zone, sponsored by Sherwin Williams | MetalVue, offers a hands-on training area featuring demonstrations and education using a variety of mock-ups and materials including painted steel, aluminum, zinc, copper and other exotic materials. Training will focus on proper detailing and utilization of the right tools to enhance the skills of contractors, remodelers and others, enabling them to deliver their best, most efficient and cleanest work when installing various metal roof offerings and systems. Led by John Sheridan of Sheridan Metal Resources and his team of experts, demonstrations will be offered in English and Spanish and tools will be available for audience testing and purchase.

Explore FREE Roofing Learning Opportunities

METALCON is the foremost authority in providing top-tier education focused on the application of metal in construction and design. We harness the expertise of leading professionals in metal construction, architecture, engineering, and manufacturing to deliver unparalleled knowledge. Whether you’re a contractor, installer, architect, specifier, or building owner, METALCON offers a range of in-depth workshops and complimentary educational sessions tailored to meet your specific needs. All education sessions—excluding workshops—are included with your registration. No additional sign-up is required.

METALCON education is accredited by organizations including the AIA and the Florida DBPR.

Labor-saving products are transforming the roofing industry, offering significant benefits in terms of efficiency, cost savings, and project timelines. To stay ahead of the curve and take full advantage of these innovations, plan to attend the METALCON show in October, taking place in Las Vegas, Nevada. Gain access to the latest products, technologies, and industry insights, ensuring they remain at the forefront of the roofing industry’s evolution.