NEWTON, Mass., June 5, 2024 — For any construction project, the goal has always been using top quality building materials for the best price. It’s all about “building performance.”

“Providing education on building performance at METALCON is essential,” says Judy Geller, Vice President, METALCON. “It will help building and design professionals address performance challenges, mitigate risks and enhance resilience leading to cost savings over the lifespan of the building. Standards and codes specific to the building site provide a helpful path to improving building performance. Understanding the performance capabilities of products used in construction will certainly help building and design professionals erect higher-performing buildings.”

Several upcoming METALCON presentations look at building performance, aimed at educating builders, roofers and architects on making the best decisions for their customers. METALCON is scheduled for October 30 through November 1 at the Georgia World Congress Center in Atlanta.

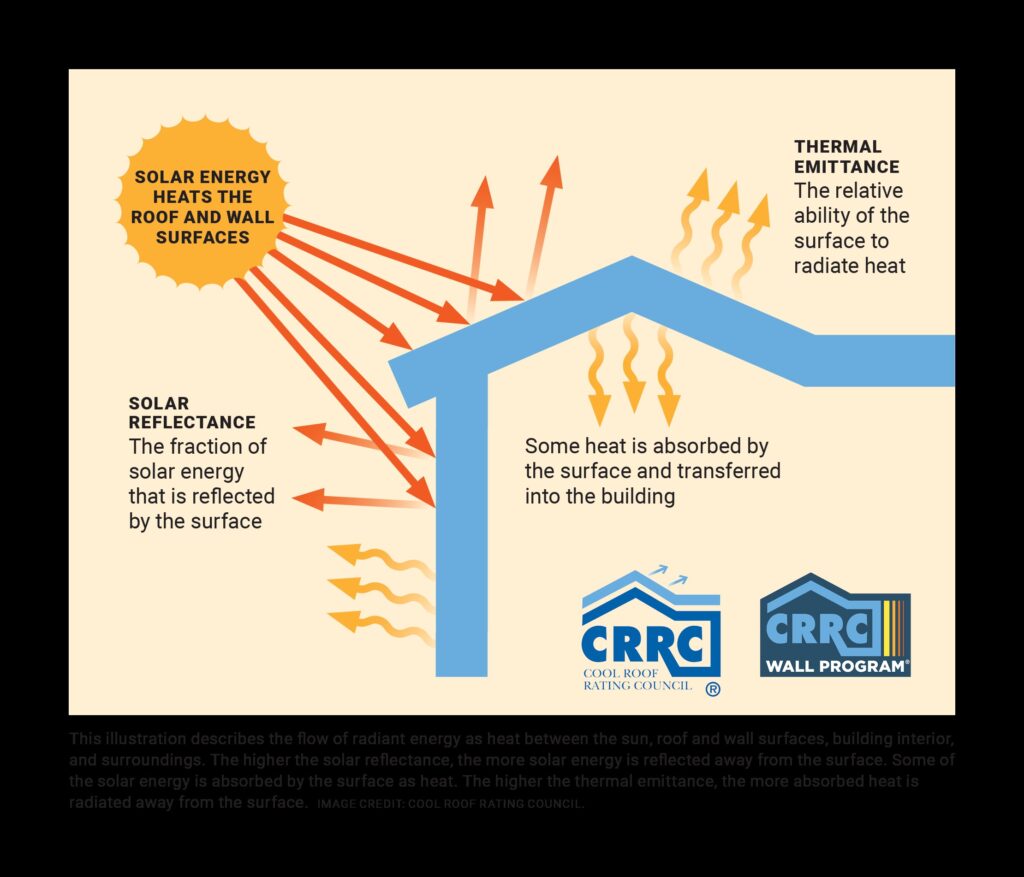

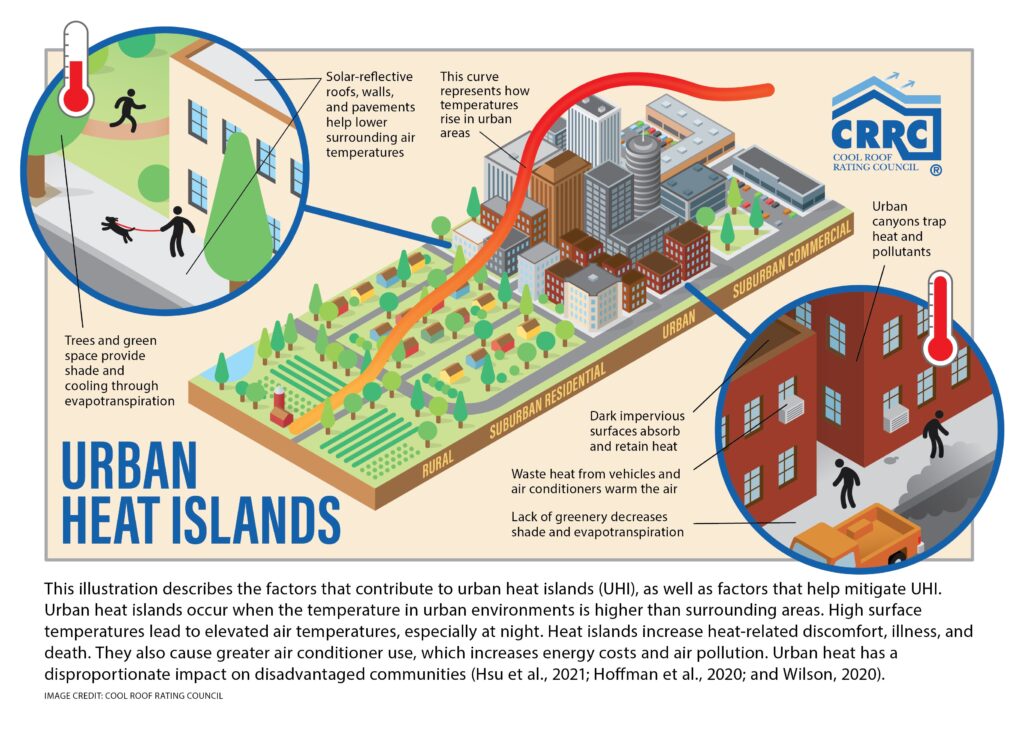

“Designing for building performance is fundamental as the building industry strives to improve energy efficiency and decrease greenhouse gas emissions originating from the built environment,” says Audrey McGarrell, Project Manager for the Cool Roof Rating Council. “Understandably, most conversations around building performance focus on systems within the building itself, but cool roofs and walls offer an opportunity to think about how the building impacts its surroundings, too. While cool surfaces help decrease cooling energy use and resulting greenhouse gas emissions, they also help mitigate the urban heat island effect in the larger community, a growing concern as cities across the U.S. get hotter.”

McGarrell’s presentation, Advancements in Cool Roof and Wall Evaluation and Compliance, is scheduled for 10:15 a.m., Oct. 31 in the Building Performance Learning Center on the METALCON show floor.

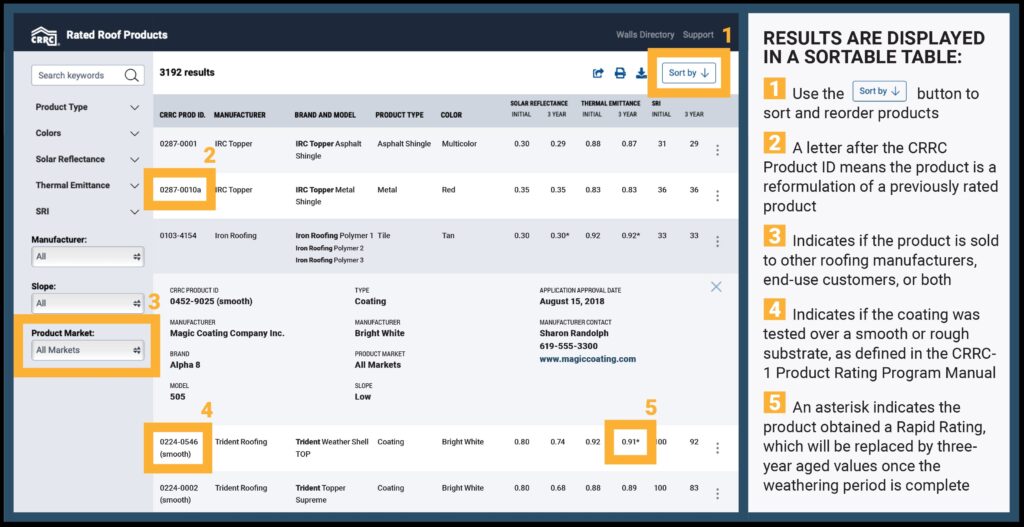

“Cool surfaces are low hanging fruit when it comes to improving energy efficiency in many climates and improving resilience to extreme heat across the entire country,” she says. “With heat waves growing longer, more frequent and more intense with each year, it’s important to consider every tool that’s available to keep buildings and their surroundings cooler. Comparing the solar reflectance and thermal emittance of different product options is easy with the CRRC’s free, publicly available Rated Products Directories.”

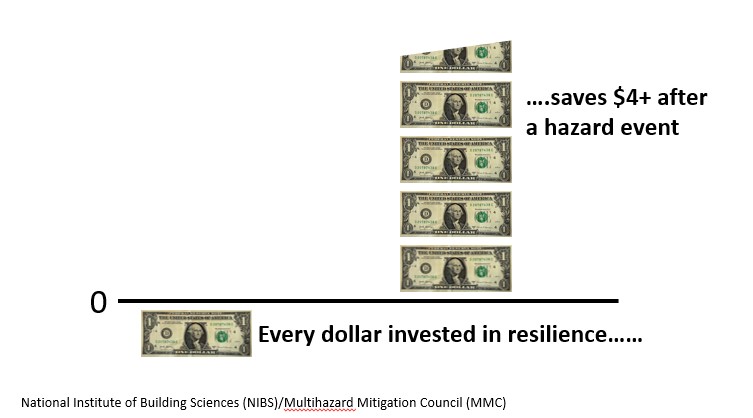

Alan Scott, Director of Sustainability Building Science Solutions Building & Construction at Intertek, is presenting, Resilient Buildings: Disaster is a Hazard You Didn’t Pay For, at 10:15 a.m., Oct. 30 at the Building Performance Learning Center.

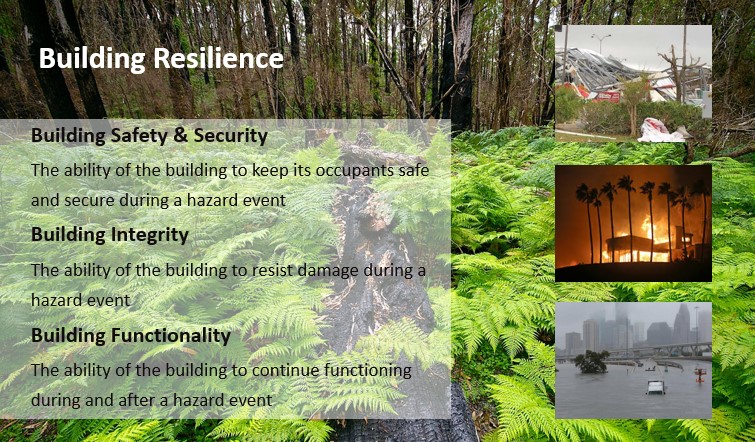

“Broadly, building performance refers to how efficiently, and most importantly, effectively a building serves its purpose and meets standards,” Scott says. “This includes reduced energy and water use, limiting greenhouse gas emissions, durability, longevity and reduced maintenance, support for human health, wellbeing and productivity (cognitive performance) and its ability to resist and recover from hazard events.”

Scott says building professionals and architects need to identify and consider current and emerging hazard risks and vulnerabilities for the building location and consider appropriate design, specification and construction options to go beyond code minimums and industry standards to create resilience and mitigate hazard vulnerabilities.

“This could mean big design moves like the location and elevation of the building site to reduce flood risks or small installation decisions like reducing the spacing of roofing and flashing fasteners in roof areas subject to the highest wind forces,” Scott says. “Minimizing hazard risk starts with hazard and vulnerability assessment, which consider natural hazards like flooding, high winds, earthquakes, tsunamis and wildfire, as well as future hazards due to climate change, such as sea level rise, extreme heat, drought and extreme rainfall.”

Bill Beals, District Manager for Therm-All, will be presenting IECC 2021 / ASHRAE 90.1-2019 Building Envelope Requirements at METALCON, taking a look at the major governing councils that mandate today’s energy codes and by differentiating various metal building insulation systems that satisfy the building requirements.

“Building performance is a compliance path to the energy codes that use modeling to determine energy usage,” Beals says. “This is compared to the standard baseline of energy usage set by the ASHRAE 90.1 Standard and or International Energy Conservation Code (IECC). This path permits a tradeoff between higher performing areas of the envelope, lighting and mechanicals, to lesser performing areas. In other words, the building performance method allows the higher performing areas to ‘pick up the slack’ for the lesser performing areas of the entire building.”

Beals says the simple version uses COMcheckTM as a tool for the building envelope, lighting and mechanical systems. The more complex version of Total Building Performance uses various computer software tools and includes the entire building. It takes into account building usage as well.

“Overall, the biggest improvements in energy efficiency and building performance stem from the building envelope,” Beals says. “Lighting and mechanicals have had an impact as well, but the increase in insulation requirements has made the most substantial contribution to building performance. Combined with the progression of air barrier requirements in each energy code cycle, the building envelope leads the charge in greatest energy savings in the overall performance of buildings.”

Energy code requirements have driven innovation, according to Beals, and through this, many proprietary systems have been introduced to the market. Each three-year energy code cycle has increased energy efficiency over previous versions from 2 to 10 percent overall. Obviously, it’s important to do your best to stay up to date.

About METALCON

METALCON is the largest international event in the metal construction and design industry. Established in 1991, it’s the only annual tradeshow and conference devoted exclusively to the application of metal in design and construction. Each year, contractors, architects, developers, owners, installers, fabricators, manufacturers and suppliers from more than 50 countries attend. 230+ leading companies exhibit the latest products, solutions and game-changing technologies. Produced by PSMJ Resources, Inc., in partnership with the Metal Construction Association, METALCON’s success is based on a dynamic exhibit hall, extensive educational programs and interactive learning opportunities. For information, visit www.metalcon.com or call 800-537-7765.

METALCON Building Performance presentations

Building Performance Learning Center, Show Floor

October 30

10:15 a.m.: Resilient Buildings: Disaster is a Hazard You Didn’t Pay For, by Alan Scott, FAIA, LEED Fellow, LEED AP BD+C, O+M, CEM WELL AP, Director of Sustainability Building Science Solutions Building & Construction, Intertek

11:45 a.m.: IECC 2021 / ASHRAE 90.1-2019 Building Envelope Requirements, by Bill Beals, District Manager, Therm-All

1:15 p.m.: How Can a Rainscreen be a High-Performance Envelope Option? by a member of RAiNA

October 31

10:15 a.m.: Advancements in Cool Roof and Wall Evaluation and Compliance, by Audrey McGarrell, Project Manager, Cool Roof Rating Council

1:15 p.m.: Introduction to ANSI/MCA FTS-1 Test Method for Windload Resistance on Flashings, by Bob Zabcik, Metal Construction Association

November 1

10:30 a.m.: Insulated Composite Backup Panels, by the MCA’s IMP Alliance, Kevin Franz, Business Development Manager, Nucor Insulated Panel Group

12 p.m.: AC472 and AC479 Accreditations for Improving Quality and Success in Metal Building Design and Construction, by MBCEA and MBMA, David Musselwhite, IAS; Dan Halme, Halme Builders; and Tony Bouquot, MBMA